Product Description:

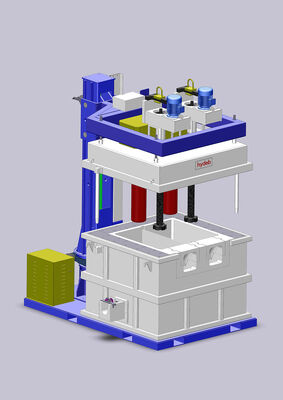

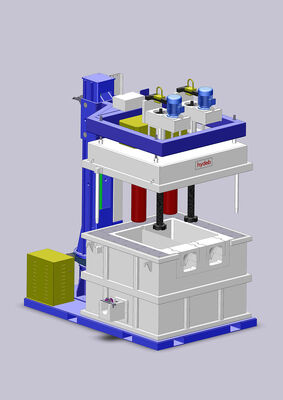

The Rotary Degassing Unit is an advanced piece of equipment designed specifically to remove dissolved gases from liquids, ensuring the highest purity and quality in metal casting applications. This Box Type In-line Rotary Degassing Unit is engineered to efficiently eliminate gases such as hydrogen, which can cause defects and weaknesses in metal castings. By effectively performing hydrogen removal, the unit plays a crucial role in enhancing the integrity and durability of metal products, making it an indispensable tool in the metal casting industry.

One of the key functions of this Rotary Degassing Unit is its ability to perform hydrogen removal with remarkable efficiency. Hydrogen, a common dissolved gas in molten metals, can lead to porosity and other casting defects if not properly removed. The unit’s design leverages a rotating mechanism that agitates the liquid, promoting the release of dissolved gases. With a rotating speed adjustable between 100 and 500 revolutions per minute (rpm), the unit provides optimal conditions for degassing, allowing operators to tailor the process according to the specific requirements of different metals and casting processes.

Powered by a three-phase four-wire power supply, the Rotary Degassing Unit ensures stable and reliable operation in demanding industrial environments. This power configuration supports consistent motor performance, which is essential for maintaining the precise rotational speeds needed to maximize degassing efficiency. The result is a robust and dependable system capable of continuous operation in the rigorous conditions typical of metal foundries.

In terms of performance, the unit boasts a degassing efficiency of 60%, which represents a significant improvement over traditional degassing methods. This high efficiency means that a substantial portion of dissolved gases, especially hydrogen, is removed from the liquid metal before casting. Consequently, this leads to fewer casting defects, better mechanical properties, and improved surface finishes. The enhanced quality of cast components directly translates into cost savings by reducing the need for rework and minimizing material waste.

The Box Type In-line Rotary Degassing Unit is designed for seamless integration into existing production lines within the metal casting industry. Its compact and modular box-type construction allows for easy installation and maintenance, reducing downtime and operational disruptions. Being an in-line system, it can degas molten metals continuously as they flow through the casting process, ensuring that hydrogen removal occurs efficiently without slowing down production cycles.

Moreover, the unit’s versatility makes it suitable for use with various metals and alloys commonly employed in casting, including aluminum, magnesium, and other non-ferrous metals where hydrogen porosity is a prevalent issue. By incorporating this rotary degassing technology, foundries can achieve higher product consistency and meet more stringent quality standards required by modern manufacturing demands.

In summary, the Rotary Degassing Unit offers a technologically advanced solution for hydrogen removal in the metal casting industry. Its ability to remove dissolved gases from liquids through a controlled rotating mechanism, powered by a reliable three-phase four-wire system, ensures enhanced degassing efficiency of up to 60%. The box type in-line design facilitates easy integration and continuous operation, making it an essential component for foundries aiming to improve casting quality and operational efficiency. By investing in this Rotary Degassing Unit, manufacturers can significantly reduce casting defects caused by hydrogen and other dissolved gases, ultimately leading to superior metal products and increased customer satisfaction.

Features:

-

Product Name: Rotary Degassing Unit

-

Degassing Method: Rotary Impeller

-

Dimensions: Depends On Model, E.g. 1200x800x1500 Mm

-

Control Type: PLC Control With Touch Screen

-

Control: PLC

-

Application: Metal Casting Industry

-

Effective Alkali Removal for improved metal quality

-

Equipped with a Rotor Degassing box for efficient gas extraction

-

Designed to enhance Alkali Removal during the degassing process

Technical Parameters:

|

Impeller Material

|

Graphite Or Ceramic

|

|

Dimensions

|

Depends On Model, E.g. 1200x800x1500 Mm

|

|

Function

|

Removes Dissolved Gases From Liquids

|

|

Temperature Range

|

Up To 800°C

|

|

Power Supply Phases

|

Three-phase Four-wire

|

|

Total Power Kw

|

<150kW

|

|

Control

|

PLC

|

|

Vacuum Range

|

0.01 To 0.1 MPa

|

|

Application

|

Metal Casting Industry

|

|

Gas Consumption

|

10-15 L/min

|

Applications:

The Hydeb BDU Rotary Degassing Unit is a highly efficient and advanced solution designed specifically for Molten Aluminium Degassing. This Box Type In-line Rotary Degassing Unit utilizes a rotary impeller degassing method, ensuring thorough removal of dissolved hydrogen and other impurities from molten aluminium. Its ability to operate at temperatures up to 800°C makes it suitable for high-temperature metallurgical processes, offering superior performance and reliability.

This unit is ideal for foundries and aluminium processing plants that require effective alkali removal and gas purification to improve the quality of their molten aluminium. The rotary impeller technology enhances gas dispersion, significantly reducing hydrogen content and minimizing defects in the final cast products. This is particularly important in industries where high-quality aluminium casting is critical, such as automotive, aerospace, and electronics manufacturing.

Equipped with a PLC control system featuring a user-friendly touch screen interface, the BDU model provides precise control over the degassing process. Operators can easily adjust parameters to optimize performance and ensure consistent quality. The unit’s gas consumption ranges from 10-15 L/min, balancing efficiency with operational cost-effectiveness.

Manufactured in China, the Hydeb BDU Rotary Degassing Unit meets stringent ISO and CE certifications, guaranteeing compliance with international quality and safety standards. Packaged securely in a wooden box for safe transportation, the unit is delivered within 50-60 days after order confirmation. Hydeb supports flexible payment terms, requiring 30% upfront and 70% upon delivery, making it accessible for various industrial budgets.

With a supply capacity of 500 sets per year, Hydeb ensures reliable availability for clients worldwide. The total power consumption of the unit is less than 150kW, making it energy-efficient without compromising on performance. This makes the BDU Rotary Degassing Unit an excellent investment for companies seeking to enhance their molten aluminium treatment processes with cutting-edge technology and robust design.

Customization:

Hydeb offers customized Rotary Degassing Unit services tailored to meet your specific needs. Our Rotary Degassing Box is designed for efficient molten aluminium treatment, ensuring effective alkali removal through advanced rotary impeller degassing methods.

The model number BDU features PLC control with a touch screen for precise operation and a rotating speed adjustable between 100-500 rpm, providing optimal performance for various production requirements.

Manufactured in China and certified with ISO CE, this unit guarantees quality and reliability. Each unit has a total power consumption of less than 150kW and a gas consumption rate of 10-15 L/min, ensuring energy-efficient operation.

We require a minimum order quantity of 1 set, with a price starting from over 30000 USD. The product is securely packaged in a wooden box to ensure safe delivery.

Delivery time ranges from 50 to 60 days, and our payment terms are 30% upfront and 70% upon delivery. With a supply ability of 500 sets per year, Hydeb is committed to meeting your production demands with high-quality rotary degassing solutions.

Support and Services:

Our Rotary Degassing Unit is designed to provide efficient and reliable removal of dissolved gases from liquids, ensuring optimal performance in various industrial and laboratory applications. For technical support, please refer to the user manual included with the product, which contains detailed instructions on installation, operation, and maintenance.

Regular maintenance is essential to ensure the longevity and efficiency of the Rotary Degassing Unit. This includes routine cleaning of the rotor and chamber, checking for any wear or damage, and replacing seals or other consumable parts as needed. Always use recommended spare parts and follow safety guidelines during maintenance procedures.

For troubleshooting common issues, verify that the unit is properly connected to power and that all tubing and fittings are secure. Ensure that the rotor is rotating smoothly without obstructions. In case of abnormal noises, leaks, or reduced degassing performance, discontinue use and consult the troubleshooting section of the manual.

We also offer comprehensive after-sales services, including calibration, repair, and technical consultation to help you maximize the unit’s performance. Our team of experts is committed to providing timely and effective support to meet your operational needs.

For detailed technical documentation, software updates, and additional resources, please visit our official website. Ensure that your Rotary Degassing Unit is registered to receive important product updates and service notifications.

Packing and Shipping:

Product Packaging:

The Rotary Degassing Unit is carefully packaged to ensure safe delivery and protection during transit. It is enclosed in a sturdy, custom-designed cardboard box with foam inserts to cushion the unit and prevent any movement. All delicate components are individually wrapped with anti-static and anti-shock materials. The packaging also includes a user manual, warranty card, and all necessary accessories securely packed in separate compartments.

Shipping:

The Rotary Degassing Unit is shipped via reliable courier services with tracking options available. We offer multiple shipping methods including standard, expedited, and overnight delivery to accommodate your needs. The product is insured against damage or loss during shipment. Prior to dispatch, each unit undergoes thorough inspection and testing to ensure optimal performance upon arrival. International shipping is available with customs documentation provided as required.

FAQ:

Q1: What is the brand and model number of the Rotary Degassing Unit?

A1: The Rotary Degassing Unit is branded as Hydeb and the model number is BDU.

Q2: Where is the Rotary Degassing Unit manufactured?

A2: The Rotary Degassing Unit is manufactured in China.

Q3: What certifications does the Rotary Degassing Unit have?

A3: The Rotary Degassing Unit is certified with ISO and CE certifications.

Q4: What is the minimum order quantity and the price for the Rotary Degassing Unit?

A4: The minimum order quantity is 1 unit, and the price is above 30000 USD.

Q5: What are the packaging details and delivery time for the Rotary Degassing Unit?

A5: The product is packaged in a wooden box, and the delivery time is approximately 50-60 days.

Q6: What are the payment terms and supply ability for the Rotary Degassing Unit?

A6: The payment terms are 30% in advance and 70% before delivery. The supply ability is 500 sets per year.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!