Product Description:

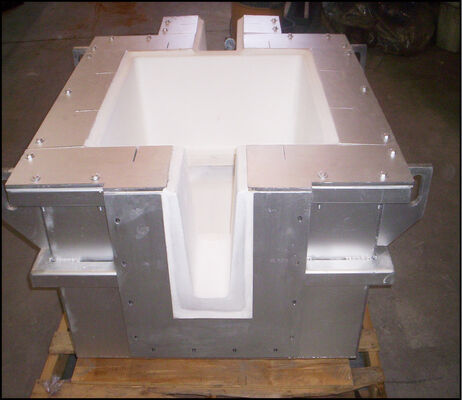

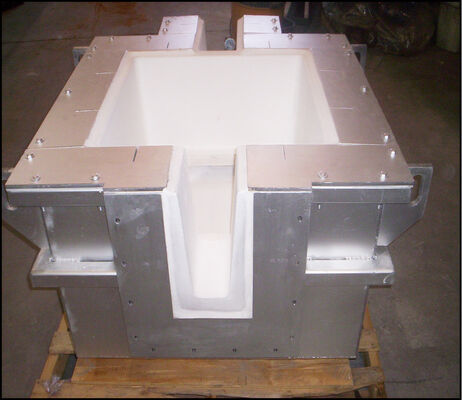

The Rotary Degassing Unit is an advanced and efficient solution designed specifically for the aluminum casting industry, addressing the critical need for high-quality molten aluminium treatment. This state-of-the-art equipment utilizes a rotor degassing box to perform molten aluminium degassing with remarkable precision and effectiveness, ensuring the production of superior cast products with minimal defects.

Operating on a reliable voltage supply of 220V or 380V, the Rotary Degassing Unit is adaptable to various industrial settings, providing flexibility and convenience for foundries of all sizes. Its robust design incorporates a water cooling system, which plays a vital role in maintaining optimal operating temperatures during the degassing process. This cooling mechanism not only prolongs the lifespan of the unit but also enhances operational safety, making it ideal for continuous production environments.

Molten aluminium degassing is a crucial step in the aluminum casting process, as it removes dissolved hydrogen and other impurities that can cause porosity, weakness, and surface defects in the final cast products. The Rotary Degassing Unit excels in this function by employing a rotor degassing box that introduces inert gases such as argon or nitrogen into the molten metal. The rotor’s dynamic action disperses these gases uniformly, facilitating the efficient removal of unwanted gases and inclusions from the molten aluminium.

One of the standout features of this unit is its impressive degassing efficiency, which reaches up to 60%. This high level of performance ensures that the molten aluminium is thoroughly purified, significantly improving the mechanical properties and surface finish of the castings. By effectively reducing gas content and inclusions, the Rotary Degassing Unit helps foundries achieve higher yield rates and reduce the incidence of rework or scrap, ultimately contributing to cost savings and enhanced productivity.

Moreover, the degassing time on this unit is fully adjustable, ranging from 0 to 99 minutes, allowing operators to tailor the process duration according to specific casting requirements and material characteristics. This flexibility ensures optimal treatment for different aluminum alloys and casting conditions, providing consistent and repeatable results. The easy-to-use control system enables precise time settings, making it user-friendly and convenient for foundry personnel.

In addition to its technical capabilities, the Rotary Degassing Unit is designed with durability and ease of maintenance in mind. The water cooling system helps prevent overheating of critical components, reducing wear and tear and minimizing downtime. The robust rotor degassing box is constructed from high-quality materials resistant to the corrosive environment of molten aluminium, ensuring long service life and reliable performance.

Overall, the Rotary Degassing Unit represents a significant advancement in molten aluminium processing technology. Its combination of adjustable degassing time, high degassing efficiency, and integrated water cooling system makes it an indispensable tool for any aluminum casting operation seeking to enhance product quality and operational efficiency. By incorporating this unit into their production line, foundries can achieve better control over molten aluminium purity, resulting in stronger, more consistent castings and improved customer satisfaction.

Whether you are upgrading your current molten aluminium degassing setup or implementing new casting processes, the Rotary Degassing Unit offers a proven and effective solution. Its precise control features, robust construction, and superior degassing performance make it the preferred choice for modern aluminum casting facilities aiming to meet stringent quality standards and optimize their production workflow.

Features:

-

Product Name: Rotary Degassing Unit

-

Degassing Efficiency: 60%

-

Power Source: Electric

-

Vacuum Level: Adjustable, Up To 0.1 Mbar

-

Rotor Speed: 100-600 Rpm

-

Degassing Method: Rotary Impeller

-

Effective Hydrogen Removal for improved purity

-

Advanced Impurity Removal technology

-

Optimized rotary design for enhanced degassing performance

Technical Parameters:

|

Voltage

|

220V/380V

|

|

Dimensions

|

Dependent On Model, E.g., 500x300x400 Mm

|

|

Vacuum Level

|

Adjustable, Up To 0.1 Mbar

|

|

Cooling System

|

Water Cooling

|

|

Operation Mode

|

Rotary Vacuum Degassing

|

|

Degassing Efficiency

|

60%

|

|

Power Source

|

Electric

|

|

Gas Inlet Pressure

|

0.4-0.6 MPa

|

|

Application

|

Aluminum Casting Industry

|

|

Degassing Method

|

Rotary Impeller

|

Applications:

The Hydeb Rotary Degassing Unit, model BDU, is a cutting-edge solution designed specifically for the aluminum casting industry. Manufactured in China and certified with ISO and CE standards, this unit ensures high-quality performance and reliability. With a supply ability of 500 sets per year, it caters to the demanding needs of large-scale industrial operations. The unit is packaged securely in a wooden box to guarantee safe delivery within 50 to 60 days after order confirmation. Pricing starts at over 30,000 USD with flexible payment terms of 30% upfront and 70% upon delivery.

This Rotary Vacuum Degassing unit excels in Hydrogen Removal, a critical process in aluminum casting that directly impacts the quality and integrity of the final product. The rotary vacuum degassing operation mode, combined with an adjustable vacuum level up to 0.1 Mbar and a maximum pressure of 0.1MPa, allows for precise control over the degassing environment. This ensures effective Hydrogen Removal by removing dissolved hydrogen gas from molten aluminum, preventing defects such as porosity and improving mechanical properties.

The BDU model features an adjustable degassing time ranging from 0 to 99 minutes, offering flexibility to meet different production requirements and optimize efficiency. Its advanced rotary mechanism enhances the degassing process by promoting uniform agitation of the molten metal, which accelerates Hydrogen Removal and reduces processing time. This makes it ideal for foundries focusing on high-quality aluminum castings for automotive, aerospace, and other industrial applications.

In practical application scenarios, the Hydeb Rotary Degassing Unit is indispensable during the melting and refining stages in aluminum casting plants. It is particularly useful in environments where maintaining the purity of aluminum is paramount, such as in the production of structural components and precision parts. Operators benefit from the unit’s user-friendly interface and robust design, which supports continuous operation and easy maintenance.

Overall, the Hydeb BDU Rotary Degassing Unit is a vital piece of equipment for any aluminum casting industry professional aiming to enhance product quality through efficient Hydrogen Removal. Its combination of advanced technology, compliance with international certifications, and customizable operational parameters ensures it meets the stringent demands of modern metal casting processes.

Customization:

Hydeb presents the Rotary Degassing Unit, model BDU, an advanced In-line Rotary Degassing Unit designed for efficient impurity removal. Manufactured in China and certified with ISO and CE, this Rotor Degassing box ensures high performance and reliability in degassing processes.

Featuring a rotary impeller degassing method, the unit operates at an adjustable vacuum level up to 0.1 Mbar, with rotor speeds ranging from 100 to 600 rpm. It delivers a degassing efficiency of 60%, maintaining a maximum pressure of 0.1MPa to meet diverse industrial requirements.

With a supply ability of 500 sets per year, Hydeb offers this product with a minimum order quantity of 1 set. The Rotary Degassing Unit is carefully packaged in a wooden box to ensure safe delivery, with an estimated delivery time of 50-60 days. Payment terms are structured as 30% advance and 70% upon delivery, with pricing starting at over 30000 USD.

Choose Hydeb’s Rotary Degassing Unit for superior impurity removal performance in your processes, supported by trusted brand quality and comprehensive customization services tailored to your operational needs.

Support and Services:

Our Rotary Degassing Unit is designed to efficiently remove dissolved gases from liquids, ensuring optimal performance in various industrial and laboratory applications. For technical support, please refer to the user manual provided with the unit, which includes detailed instructions on installation, operation, and maintenance.

We recommend regular maintenance checks to ensure the longevity and reliability of the Rotary Degassing Unit. This includes inspecting seals and connections for leaks, cleaning the rotor and chamber to prevent buildup, and verifying the vacuum pump function.

Should you encounter any issues with the unit's performance, please consult the troubleshooting section of the manual. Common issues such as reduced degassing efficiency or unusual noises can often be resolved through routine maintenance or adjustments as described.

For software updates, calibration services, or advanced technical support, please contact our authorized service centers. Our trained technicians are available to assist with installation guidance, repair services, and performance optimization.

We are committed to providing comprehensive support to ensure your Rotary Degassing Unit operates at peak efficiency, helping you achieve accurate and reliable results in your processes.

Packing and Shipping:

Product Packaging:

The Rotary Degassing Unit is carefully packaged to ensure safe transportation and delivery. Each unit is securely placed in a custom-fitted foam insert within a sturdy, double-walled cardboard box. The packaging includes protective corner guards and anti-static materials to prevent any damage from shocks, vibrations, or electrostatic discharge during shipping. All accessories, manuals, and cables are neatly organized and packed alongside the main unit. The outer box is clearly labeled with handling instructions and product information for easy identification.

Shipping:

Our Rotary Degassing Unit is shipped via reliable courier services with tracking and insurance options available. We offer worldwide shipping with estimated delivery times provided at the time of order confirmation. Prior to dispatch, each unit undergoes a quality control check to ensure it meets all specifications and performance standards. Customers will receive a shipping confirmation email containing tracking details to monitor the shipment progress. For international shipments, all necessary customs documentation is prepared to facilitate smooth clearance and timely delivery.

FAQ:

Q1: What is the brand and model number of the Rotary Degassing Unit?

A1: The Rotary Degassing Unit is branded as Hydeb, and the model number is BDU.

Q2: Where is the Hydeb Rotary Degassing Unit manufactured?

A2: The Hydeb Rotary Degassing Unit is manufactured in China.

Q3: What certifications does the Rotary Degassing Unit have?

A3: The Rotary Degassing Unit is certified with ISO and CE certifications.

Q4: What is the minimum order quantity and price for the Hydeb Rotary Degassing Unit?

A4: The minimum order quantity is 1 unit, and the price starts from over 30,000 USD.

Q5: How is the Rotary Degassing Unit packaged and what is the delivery time?

A5: The unit is packaged in a wooden box, and the delivery time is approximately 50-60 days.

Q6: What are the payment terms for purchasing the Hydeb Rotary Degassing Unit?

A6: The payment terms are 30% deposit in advance and 70% before delivery.

Q7: What is the annual supply ability for the Hydeb Rotary Degassing Unit?

A7: Hydeb can supply up to 500 sets of the Rotary Degassing Unit per year.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!