Product Description:

The Rotary Degassing Unit is an advanced solution designed to efficiently remove dissolved gases from liquids, playing a crucial role in various industrial processes. Known for its reliability and robust construction, this unit is specifically engineered to optimize alkali removal, ensuring high-quality output and enhanced process stability. The device is widely recognized as an in-line rotary degassing unit, which seamlessly integrates into existing production lines, providing continuous and effective degassing without interrupting workflow.

At the heart of the Rotary Degassing Unit is the rotary degassing box, a carefully designed component that facilitates thorough gas elimination. The rotary mechanism operates at a rotor speed adjustable between 100 to 600 revolutions per minute (Rpm), allowing for flexible control according to the specific degassing requirements of different applications. This adjustable speed range ensures that the unit can handle varying flow rates and liquid properties, maintaining optimal performance across diverse industrial settings.

One of the standout features of this rotary degassing box is its ability to function efficiently under a maximum pressure of 0.1 MPa. This capability is complemented by a gas inlet pressure range of 0.4 to 0.6 MPa, which guarantees a consistent and controlled environment for the degassing process. These pressure parameters are critical for achieving effective alkali removal, as they help maintain the delicate balance needed to extract dissolved gases without compromising the integrity of the liquid being treated.

The Rotary Degassing Unit is designed with practicality and user convenience in mind. Its dimensions — 1200mm in length, 800mm in width, and 1500mm in height — make it compact enough to fit into a variety of industrial setups while providing ample space for maintenance and operation. Despite its relatively moderate size, the unit is constructed from durable materials, ensuring long-lasting performance even in demanding environments.

Powering the unit is a reliable electric system available in both 220V and 380V voltage options, catering to different regional power standards and industrial requirements. This flexibility in voltage supply not only makes the unit versatile but also easy to integrate into existing facilities without the need for extensive electrical modifications. The robust electrical system supports the rotary mechanism and other operational components, ensuring smooth and uninterrupted degassing processes.

In addition to its technical specifications, the in-line rotary degassing unit offers several operational advantages. Its continuous operation mode allows for real-time gas removal, significantly reducing downtime and boosting overall productivity. The rotary degassing box design minimizes maintenance needs by reducing wear and tear, while its efficient alkali removal capabilities help improve the quality and stability of the final product. This makes the unit an indispensable asset in industries where precise gas control is essential, such as chemical manufacturing, water treatment, and pulp and paper processing.

In summary, the Rotary Degassing Unit combines advanced engineering with practical features to deliver superior degassing performance. Its maximum pressure capacity of 0.1 MPa, adaptable rotor speed between 100 and 600 Rpm, and gas inlet pressure of 0.4 to 0.6 MPa create an ideal environment for effective alkali removal. The compact dimensions of 1200mm x 800mm x 1500mm and dual voltage options of 220V/380V further enhance its adaptability and ease of integration. As an in-line rotary degassing unit featuring a rotary degassing box, it stands out as a reliable and efficient solution for industries seeking to optimize their degassing processes and improve product quality.

Features:

-

Product Name: Rotary Degassing Unit

-

Also known as Rotary Degassing Box

-

Box Type In-line Rotary Degassing Unit for efficient degassing

-

Voltage options: 220V / 380V

-

Adjustable Degassing Time: 0~99 minutes

-

Cooling System: Water Cooling for optimal temperature control

-

Gas Inlet Pressure: 0.4-0.6 MPa

-

Application: Specifically designed for the Aluminum Casting Industry

Technical Parameters:

|

Rotor Speed

|

100-600 Rpm

|

|

Degass Efficiency

|

60%

|

|

Degassing Time

|

0~99 Adjustable

|

|

Degassing Method

|

Rotary Impeller

|

|

Operation Mode

|

Rotary Vacuum Degassing

|

|

Power Source

|

Electric

|

|

Dimensions

|

Dependent On Model, E.g., 500x300x400 Mm; 1200mm X 800mm X 1500mm

|

|

Cooling System

|

Water Cooling

|

|

Application

|

Aluminum Casting Industry - Molten Aluminium Degassing, Box Type In-line Rotary Degassing Unit, Rotor Degassing box

|

Applications:

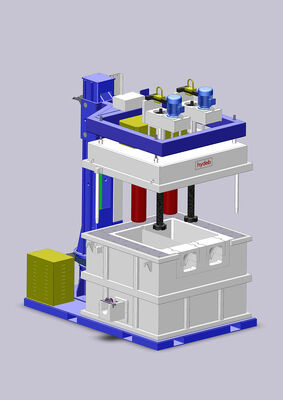

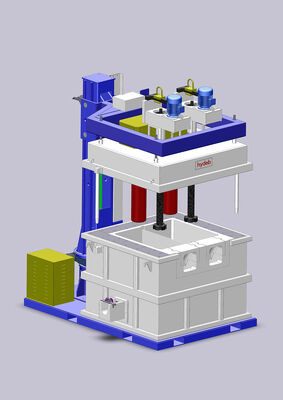

The Hydeb Rotary Degassing Unit (Model BDU) is an advanced piece of equipment designed specifically for the aluminum casting industry, offering efficient and reliable alkali removal during the molten aluminum processing stage. Manufactured in China and certified with ISO and CE standards, this Box Type In-line Rotary Degassing Unit ensures high-quality performance and safety compliance, making it an ideal solution for foundries and metal processing plants seeking to improve their casting quality.

The Rotary Degassing Box operates using an electric power source and utilizes a rotary vacuum degassing operation mode. This technique effectively removes hydrogen, alkali metals, and other impurities from molten aluminum, enhancing the metal’s purity and improving the mechanical properties of the final cast products. The unit is designed to handle gas inlet pressures between 0.4 to 0.6 MPa, ensuring optimal degassing efficiency under various industrial conditions.

With dimensions dependent on the specific model, for example, 500x300x400 mm, the Hydeb BDU is compact yet robust, making it suitable for integration into existing production lines without requiring extensive modifications. The product is delivered in sturdy wooden box packaging to guarantee safe transportation, with a delivery time of approximately 50-60 days. Hydeb offers flexible payment terms of 30% upfront and 70% upon delivery, accommodating various procurement preferences.

Ideal application occasions for the Hydeb Rotary Degassing Unit include aluminum casting foundries focusing on producing high-quality castings with improved mechanical strength and minimal defects. It is particularly beneficial in scenarios where alkali removal is critical to reduce porosity and enhance the overall integrity of aluminum alloys. The unit's rotary vacuum degassing mechanism ensures continuous and efficient degassing, supporting large-scale production environments with a supply ability of up to 500 sets per year.

Whether used in primary aluminum smelting plants or secondary aluminum recycling processes, the Hydeb BDU Rotary Degassing Box delivers consistent results, making it a valuable asset for metal processing industries aiming to achieve superior casting quality. With a minimum order quantity of 1 set and a price exceeding 30,000 USD, this equipment represents a significant investment toward optimizing aluminum casting operations and improving product standards in competitive markets.

Customization:

The Hydeb Rotary Degassing Unit (Model Number: BDU) is a highly efficient Box Type In-line Rotary Degassing Unit designed specifically for molten aluminium treatment. With a degassing efficiency of 60%, this unit effectively removes alkali and other impurities to improve metal quality.

Manufactured in China and certified with ISO and CE standards, the Rotary Degassing Unit ensures reliable performance and compliance with international quality requirements. The vacuum level is adjustable up to 0.1 Mbar, allowing precise control during the degassing process.

The unit's dimensions vary depending on the model, for example, 500x300x400 mm, with a typical dimension of 1200mm x 800mm x 1500mm, making it suitable for various production needs. Each unit is carefully packaged in a sturdy wooden box to ensure safe delivery.

With a supply ability of 500 sets per year, Hydeb can fulfill orders promptly, with a minimum order quantity of 1 set. The delivery time is approximately 50-60 days, and payment terms are 30% upfront and 70% upon completion. Pricing starts above 30000 USD.

The Hydeb Rotary Degassing Unit is the ideal solution for enhancing molten aluminium quality through efficient alkali removal and reliable in-line degassing performance.

Support and Services:

Our Rotary Degassing Unit is designed to efficiently remove dissolved gases from liquids, ensuring optimal performance in various industrial and laboratory applications. For technical support, please refer to the user manual included with your unit, which provides detailed instructions on installation, operation, and maintenance.

Regular maintenance is essential to maintain the effectiveness of the degassing unit. Clean the rotary components and check for any signs of wear or damage periodically. Replace any worn parts promptly to avoid operational issues.

If you encounter any technical problems or require service beyond routine maintenance, our team of experts is available to assist with troubleshooting, repairs, and replacement parts. We recommend using only authorized service providers to ensure the integrity and safety of your equipment.

For software updates, calibration guidelines, and additional resources, please visit our official website. We also offer training sessions and detailed documentation to help you maximize the performance and lifespan of your Rotary Degassing Unit.

Your satisfaction and the reliable operation of your equipment are our top priorities. Please ensure all safety protocols are followed during operation and maintenance to prevent accidents and equipment damage.

Packing and Shipping:

The Rotary Degassing Unit is carefully packaged to ensure safe delivery and optimal performance upon arrival. Each unit is securely placed in a custom-fitted foam insert within a sturdy, double-walled cardboard box to protect against shocks and vibrations during transit.

All components are individually wrapped and sealed to prevent contamination and damage. The packaging includes clear instructions for unpacking and handling to facilitate easy setup.

For shipping, the Rotary Degassing Unit is dispatched via reliable carriers with tracking options available. We recommend selecting expedited shipping for urgent orders to minimize transit time. Additionally, all shipments are insured to provide peace of mind against loss or damage.

Upon receiving your Rotary Degassing Unit, please inspect the packaging for any signs of damage before opening. In the unlikely event of any issues, contact our customer service team immediately for assistance.

FAQ:

Q1: What is the brand and model number of the Rotary Degassing Unit?

A1: The Rotary Degassing Unit is manufactured by Hydeb and the model number is BDU.

Q2: Where is the Rotary Degassing Unit made?

A2: The Rotary Degassing Unit is made in China.

Q3: What certifications does the Rotary Degassing Unit have?

A3: The Rotary Degassing Unit is certified with ISO and CE.

Q4: What is the minimum order quantity and price for the Rotary Degassing Unit?

A4: The minimum order quantity is 1 unit, and the price starts from over 30,000 USD.

Q5: What are the packaging details and delivery time for the Rotary Degassing Unit?

A5: The Rotary Degassing Unit is packaged in a wooden box, and the delivery time is 50-60 days.

Q6: What are the payment terms and supply ability for the Rotary Degassing Unit?

A6: The payment terms are 30% in advance and 70% before delivery. The supply ability is 500 sets per year.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!