Product Description:

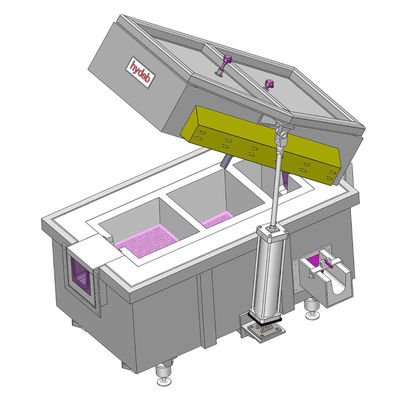

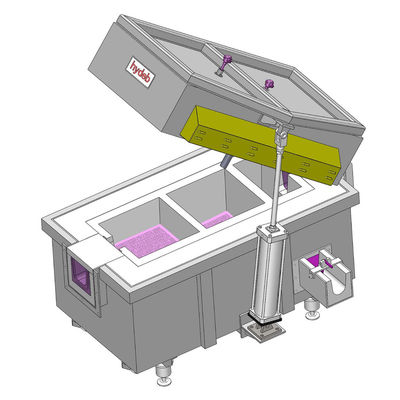

The Rotary Degassing Unit is a high-efficiency degassing system designed for the removal of hydrogen and alkali from molten metal. With a degassing efficiency of 60%, this innovative degassing unit ensures excellent performance in purifying the metal and enhancing its quality.

Featuring a total power of less than 47 kW, the Rotary Degassing Unit is an energy-efficient solution that helps reduce operational costs while delivering superior degassing results. The low power consumption makes it a sustainable choice for metal processing facilities looking to optimize their operations.

For efficient cooling during operation, the Rotary Degassing Unit requires a minimal cooling water consumption of 5 liters per minute. This efficient use of cooling water not only contributes to cost savings but also ensures the proper functioning and longevity of the degassing unit.

Equipped with a state-of-the-art PLC control system, the Rotary Degassing Unit offers precise and reliable control over the degassing process. The advanced control system allows operators to easily adjust and monitor the degassing parameters, ensuring consistent and optimized performance throughout the operation.

The Rotary Degassing Unit features a variable rotor speed ranging from 100 to 600 rpm, providing flexibility to tailor the degassing process according to specific metal compositions and processing requirements. The adjustable rotor speed enables fine-tuning of the degassing performance for optimal results.

Designed as a box type in-line rotary degassing unit, this system is engineered for seamless integration into metal casting and processing lines. Its compact and efficient design allows for easy installation and operation within existing production setups, enhancing overall workflow efficiency.

Overall, the Rotary Degassing Unit offers a comprehensive solution for effective hydrogen removal, alkali removal, and overall metal purification. With its high degassing efficiency, energy-efficient operation, precise control system, variable rotor speed, and compact design, this degassing unit is ideal for metal processing facilities seeking to improve the quality and integrity of their products.

Features:

-

Product Name: Rotary Degassing Unit

-

Max Pressure: 2 Bar

-

Cooling Water Consumption: 5 L/min

-

Cooling System: Water Cooling

-

Power Consumption: 2-3 KW

-

Max Temperature: 1200°C

Technical Parameters:

|

Max Temperature

|

1200°C

|

|

Control System

|

PLC

|

|

Dimension

|

1200mm X 800mm X 1500mm

|

|

Degassing Time

|

0~99 Adjustable

|

|

Cooling System

|

Water Cooling

|

|

Max Pressure

|

2 Bar

|

|

Vacuum Degree

|

≤10 Pa

|

|

Fluxing Size

|

Less Than 5 Mm

|

|

Number Of Rotors

|

1-3

|

|

Degassing Efficiency

|

60%

|

Applications:

Hydeb's Rotary Degassing Unit, model BDU, is a top-of-the-line product designed for efficient degassing of molten aluminum in various industrial applications. With ISO CE certification, this high-quality equipment is suitable for a wide range of scenarios.

Product Application Occasions and Scenarios:

- Foundries: The Rotary Degassing Unit can be used in foundries for degassing molten aluminum before casting, ensuring high-quality finished products.

- Aluminum Production Plants: The Rotor Degassing box is essential for maintaining the purity of molten aluminum, leading to improved mechanical properties of the final aluminum products.

- Automotive Industry: Manufacturers in the automotive sector can benefit from using the Rotary Degassing Unit to enhance the quality of aluminum components used in vehicle production.

With a maximum pressure of 2 Bar and a maximum temperature of 1200°C, the Rotary Degassing Unit is capable of handling demanding industrial processes. The unit's dimensions of 1200mm x 800mm x 1500mm make it space-efficient for various factory layouts.

Equipped with a water cooling system, the Rotary Degassing Unit ensures optimal performance even during prolonged operations. The PLC control system allows for precise adjustments and monitoring, contributing to operational efficiency.

Hydeb offers the Rotary Degassing Unit with a minimum order quantity of 1, packaged securely in a wooden box for safe transportation. The price of the unit is set at over 30000USD, reflecting its advanced features and quality construction.

Customers can expect a delivery time of 50-60 days, with payment terms of 30% upfront and 70% upon delivery. Hydeb's supply ability of 500 sets per year ensures prompt availability of the Rotary Degassing Unit for industrial applications.

Customization:

Product Customization Services for the Rotary Degassing Unit:

Brand Name:

Hydeb

Model Number:

BDU

Certification:

ISO CE

Minimum Order Quantity:

1

Price:

>30000USD

Packaging Details:

Wooden Box

Delivery Time:

50-60 Days

Payment Terms:

30%+70%

Supply Ability:

500 Sets Per Year

Dimension:

1200mm X 800mm X 1500mm

Max Temperature:

1200°C

Degassing Efficiency:

60%

Cooling System:

Water Cooling

Fluxing Size:

Less Than 5mm

Keywords: Impurity Removal, Box Type In-line Rotary Degassing Unit, Impurity Removal

Support and Services:

The Rotary Degassing Unit product technical support and services are designed to provide comprehensive assistance to customers using the product. Our team of technical experts is available to address any questions or issues related to the operation, maintenance, and troubleshooting of the Rotary Degassing Unit. Additionally, we offer training programs to help customers maximize the performance and efficiency of the unit. Our goal is to ensure that customers can fully benefit from the features and capabilities of the Rotary Degassing Unit.

Packing and Shipping:

Product Packaging:

The Rotary Degassing Unit is carefully packaged in a sturdy cardboard box to ensure its safe delivery. The unit is securely padded with foam inserts to prevent any damage during transit. Each component is individually wrapped and labeled for easy identification.

Shipping:

We ship the Rotary Degassing Unit using a reliable courier service to ensure timely and safe delivery to your location. The package is sealed securely to protect the contents from any external elements during transportation. A tracking number will be provided so you can monitor the status of your shipment.

FAQ:

Q: What is the brand name of this Rotary Degassing Unit?

A: The brand name is Hydeb.

Q: What is the model number of this unit?

A: The model number is BDU.

Q: Does this unit come with any certifications?

A: Yes, it is certified with ISO and CE.

Q: What is the minimum order quantity for this product?

A: The minimum order quantity is 1 unit.

Q: What is the price range for this Rotary Degassing Unit?

A: The price is greater than 30000 USD.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!