Product Description:

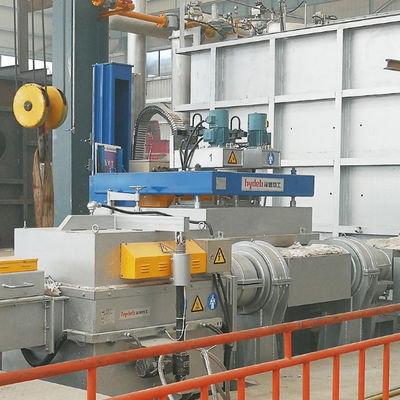

The Rotary Degassing Unit is a high-quality product designed for efficient and effective degassing of molten aluminum in the metal casting industry. With its advanced features and reliable performance, this unit is an essential tool for ensuring high-quality aluminum products free from impurities.

One of the key features of the Rotary Degassing Unit is its rotary degassing capability, which allows for thorough mixing and removal of alkali and hydrogen from the molten aluminum. This process is crucial for enhancing the overall quality and properties of the aluminum, making it suitable for a wide range of applications.

Equipped with vacuum degassing technology, this unit creates a controlled environment for the degassing process, ensuring optimal results and minimal impurities in the final product. The inert gas injection feature further enhances the degassing process by displacing unwanted gases and improving the overall quality of the aluminum.

Operating at a voltage of 220V/380V and powered by electricity, the Rotary Degassing Unit is both powerful and efficient, making it suitable for industrial applications requiring high levels of degassing performance. The unit's shaft material, graphite, is known for its durability and resistance to high temperatures, ensuring long-lasting performance and reliability.

Designed to be lifted by crane, the Rotary Degassing Unit offers flexibility and ease of use in various industrial settings. Its robust construction and user-friendly design make it a valuable asset for metal casting facilities looking to enhance their aluminum production processes.

In summary, the Rotary Degassing Unit is a versatile and reliable tool for alkali removal, hydrogen removal, and overall improvement of molten aluminum quality. With its advanced features, durable construction, and efficient performance, this unit is a must-have for metal casting operations aiming to achieve high-quality aluminum products for various industries.

Features:

- Product Name: Rotary Degassing Unit

- Operation Mode: Automatic

- Voltage: 220V/380V

- Power Consumption: 5-10 KW

- Shaft Material: Graphite

- Features:

- Rotary Degassing

- Vacuum Degassing

- Inert Gas Injection

Technical Parameters:

| Voltage |

220V/380V |

| Application |

Aluminum Casting |

| Max Temperature |

1200°C |

| Power Source |

Electric |

| Features |

Rotary Degassing, Vacuum Degassing, Inert Gas Injection |

| Operation Mode |

Automatic |

| Control |

PLC |

| Capacity |

10-100 Kg |

| Shaft Material |

Graphite |

| Degassing Time |

0~99 Adjustable |

Applications:

Hydeb's BDU Rotary Degassing Unit is a high-quality product originating from China, with ISO CE certification. Designed for efficient impurity removal, this Box Type In-line Rotary Degassing Unit is suitable for a wide range of application occasions and scenarios.

With a capacity ranging from 10 to 100 Kg, the BDU is ideal for industries requiring precise degassing processes. Its electric power source, operating at either 220V or 380V with a frequency of 50Hz, ensures reliable performance.

The BDU is well-suited for various settings, such as foundries, metal casting facilities, and industrial workshops. Its shaft material made of Graphite guarantees durability and longevity, making it a reliable choice for continuous operation.

Whether it's aluminum, copper, or other metal alloys, the BDU Rotary Degassing Unit effectively removes impurities to enhance the quality of the final product. The minimum order quantity of 1 unit, priced above $30,000 USD, comes packaged in a secure wooden box for safe delivery.

Customers can expect a delivery time of 50-60 days, with payment terms set at 30% upfront and 70% upon delivery. Hydeb ensures a supply ability of 500 sets per year, catering to both small-scale operations and large industrial facilities seeking efficient degassing solutions.

Customization:

Product Customization Services for the Rotary Degassing Unit:

- Brand Name: Hydeb

- Model Number: BDU

- Place Of Origin: China

- Certification: ISO CE

- Minimum Order Quantity: 1

- Price: >30000USD

- Packaging Details: Wooden Box

- Delivery Time: 50-60 Days

- Payment Terms: 30%+70%

- Supply Ability: 500 Sets Per Year

- Degassing Time: 0~99 Adjustable

- Power Consumption: 5-10 KW

- Degassing Efficiency: 60%

- Power Supply: 220V/380V

- Features: Rotary Degassing, Vacuum Degassing, Inert Gas Injection

Customization options available for Molten Aluminium Degassing, Box Type In-line Rotary Degassing Unit, and In-line Rotary Degassing Unit.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!