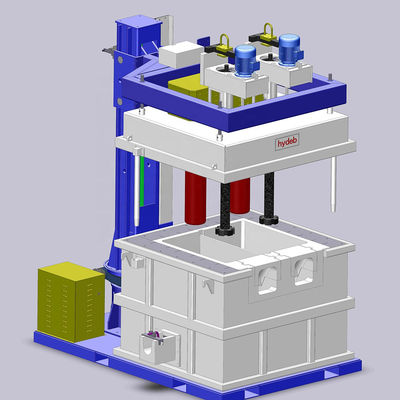

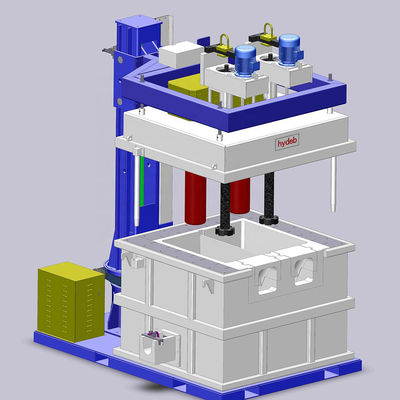

Product Description:

The Rotary Degassing Unit is a cutting-edge piece of equipment designed for efficient degassing of molten aluminum in aluminum casting applications. With advanced features and precise control, this unit is a vital tool for ensuring high-quality aluminum production.

One of the key attributes of the Rotary Degassing Unit is its state-of-the-art PLC control system. This advanced control system allows for precise and automated operation, ensuring consistent and reliable performance during the degassing process. The PLC control also provides flexibility for customization and optimization based on specific production requirements, making the unit adaptable to various casting scenarios.

When it comes to lifting capabilities, the Rotary Degassing Unit is designed to be lifted by a crane. This feature enhances the unit's portability and ease of installation, allowing for convenient positioning in different areas of the production facility as needed. The crane lifting mechanism ensures safe and efficient handling of the unit, contributing to a smooth operational workflow.

The shaft material of the Rotary Degassing Unit is made of high-quality graphite, known for its excellent thermal conductivity and durability. Graphite shafts are ideal for molten aluminum degassing applications due to their resistance to thermal shock and corrosive environments. The use of graphite shaft material ensures long-lasting performance and reliability, making the unit a valuable asset for continuous production processes.

With a degassing time range of 0 to 99 adjustable, the Rotary Degassing Unit offers precise control over the degassing process duration. This adjustable degassing time feature allows operators to fine-tune the degassing cycle based on specific requirements, ensuring optimal gas removal efficiency and quality of the molten aluminum. The flexibility in degassing time settings makes the unit versatile for various casting scenarios and production volumes, catering to diverse manufacturing needs.

The primary application of the Rotary Degassing Unit is in aluminum casting processes, where the removal of alkali and other impurities from molten aluminum is crucial for achieving high-quality castings. The unit plays a critical role in molten aluminum degassing, effectively removing dissolved gases such as hydrogen and alkali metals to enhance the mechanical properties and surface finish of the cast aluminum parts. By employing the Rotary Degassing Unit in the casting process, manufacturers can improve the overall quality and integrity of their aluminum products, meeting stringent industry standards and customer expectations.

In conclusion, the Rotary Degassing Unit is a sophisticated and reliable solution for enhancing the quality of molten aluminum in aluminum casting applications. With its advanced PLC control, crane-liftable design, graphite shaft material, adjustable degassing time, and focus on alkali removal and molten aluminum degassing, this unit offers unparalleled performance and efficiency in the production environment. Investing in the Rotary Degassing Unit is a strategic decision for manufacturers looking to optimize their casting processes and deliver superior aluminum products to the market.

Features:

- Product Name: Rotary Degassing Unit

- Voltage: 220V/380V

- Application: Aluminum Casting

- Frequency Hz: 50

- Control: PLC

- Operation Mode: Automatic

Technical Parameters:

| Power Supply |

220V/380V |

| Shaft Material |

Graphite |

| Control |

PLC |

| Power Consumption |

5-10 KW |

| Application |

Aluminum Casting |

| Operation Mode |

Automatic |

| Lifted |

By Crane |

| Power Source |

Electric |

| Max Temperature |

1200°C |

| Degassing Time |

0~99 Adjustable |

Applications:

Hydeb's BDU Rotary Degassing Unit is a versatile product designed for various applications in the metal casting industry. With its advanced features and high-quality performance, the BDU is suitable for a wide range of product application occasions and scenarios.

One of the key application scenarios for the BDU is in foundries and casting facilities where Box Type In-line Rotary Degassing Units are required for efficient metal degassing processes. The BDU's ability to perform rotary degassing, vacuum degassing, and inert gas injection makes it ideal for improving the quality of castings by removing impurities such as hydrogen and alkali elements.

Thanks to its automatic operation mode, the BDU is easy to use and can be integrated seamlessly into existing production lines. Its maximum temperature of 1200°C ensures effective degassing performance even for high-temperature metal alloys.

Manufactured in China with ISO CE certification, the BDU guarantees high standards of quality and reliability. Customers can order a minimum quantity of 1 unit, with each unit priced at over $30000 USD. The product is carefully packaged in wooden boxes to ensure safe delivery, with an average lead time of 50-60 days.

Payment terms for the BDU include a 30% deposit upfront and 70% upon delivery, providing flexibility for customers. With a supply ability of 500 sets per year, Hydeb ensures that customers can rely on timely delivery of their orders.

The BDU is designed to be lifted by crane for easy installation and maintenance. It operates on either 220V or 380V voltage, catering to different power supply requirements in various facilities.

In conclusion, the Hydeb BDU Rotary Degassing Unit is a top-of-the-line product suitable for a wide range of metal casting applications. Its advanced features, reliable performance, and ease of operation make it a valuable asset for foundries and casting facilities looking to improve their casting quality and efficiency.

Customization:

Product Customization Services for the Rotary Degassing Unit:

- Brand Name: Hydeb

- Model Number: BDU

- Place Of Origin: China

- Certification: ISO CE

- Minimum Order Quantity: 1

- Price: >30000USD

- Packaging Details: Wooden Box

- Delivery Time: 50-60 Days

- Payment Terms: 30%+70%

- Supply Ability: 500 Sets Per Year

- Shaft Material: Graphite

- Voltage: 220V/380V

- Degassing Efficiency: 60%

- Operation Mode: Automatic

- Application: Aluminum Casting

Key Features: Impurity Removal, Molten Aluminium Degassing, In-line Rotary Degassing Unit

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!