Product Description:

The Rotary Degassing Unit, also known as the Rotor Degassing box, is a cutting-edge piece of equipment designed to efficiently remove gas from molten metal during the casting process. Operating in Automatic mode, this unit comes in the model BDU and offers a range of advanced features to enhance productivity and quality.

With a rotating speed of 100-500 Rpm, the Rotary Degassing Unit ensures thorough degassing of the molten metal, resulting in improved material properties and reduced defects. The unit's high-speed rotation facilitates the effective elimination of unwanted gases, leading to superior casting results.

Featuring a total power of less than 150kW, the Rotary Degassing Unit offers energy-efficient operation without compromising on performance. This makes it a cost-effective solution for metal casting facilities looking to optimize their processes while minimizing energy consumption.

The Rotary Degassing Unit can be equipped with 1 to 3 rotors, providing flexibility to meet varying production requirements. The multiple rotor configuration allows for enhanced degassing efficiency, especially in larger batches of molten metal.

Overall, the Rotary Degassing Unit, or Rotor Degassing box, is a reliable and high-performing solution for metal casting applications. Its automatic operation mode, model BDU, adjustable rotating speed, power efficiency, and multiple rotor options make it a versatile choice for foundries and casting facilities looking to achieve superior casting results and improve overall production processes.

Features:

- Product Name: Rotary Degassing Unit

- Total Power Kw: <150kW

- Degassing Time: 0~99 Adjustable

- Power Supply: 220V/380V

- Control: PLC

- Power Supply Phases: Three-phase Four-wire

Technical Parameters:

| Degassing Time |

0~99 Adjustable |

| Operation Mode |

Automatic |

| Total Power Kw |

<150kW |

| Power Supply |

220V/380V |

| Power Supply Phases |

Three-phase Four-wire |

| Model |

BDU |

| Number Of Rotors |

1-3 |

| Fluxing Size |

Less Than 5 Mm |

| Shaft Material |

Graphite |

| Dimensions |

1500×1500×1800mm |

Applications:

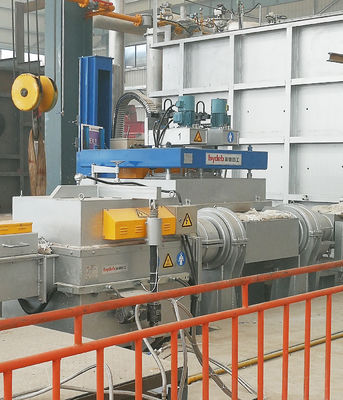

Hydeb's Rotary Degassing Unit, model BDU, is a cutting-edge product designed for the efficient degassing of molten aluminum in various industrial settings. With its origins in Shandong, China, this product boasts ISO CE certification, ensuring top-notch quality and performance.

The Rotary Degassing Unit is ideal for a wide range of product application occasions and scenarios, making it a versatile solution for industries requiring precise molten aluminum treatment. One key application is in Molten Aluminium Degassing, where the unit excels at removing hydrogen and alkali impurities from the molten metal, ensuring a high-quality end product.

Whether in aluminum casting facilities, foundries, or metalworking plants, the Rotary Degassing Unit proves to be an indispensable tool for achieving superior aluminum quality. Its minimum order quantity of 1 unit and price exceeding $30,000 USD make it accessible for businesses of various scales.

Packaged in sturdy wooden boxes, the Rotary Degassing Unit is delivered from Shandong within 50-60 days of ordering, with convenient payment terms of 30%+70%. Its supply ability of 500 sets per year ensures consistent availability for industries with high production demands.

Designed for ease of handling, the unit can be lifted by crane, offering flexibility in installation and relocation. Operating at a frequency of 50Hz and featuring a graphite shaft material, the BDU model ensures reliable and efficient degassing performance.

With dimensions of 1500×1500×1800mm, the Rotary Degassing Unit by Hydeb is a comprehensive solution for industries seeking to enhance the quality of their molten aluminum output through precise degassing processes.

Customization:

Product Customization Services for the Rotary Degassing Unit:

Brand Name: Hydeb

Model Number: BDU

Place of Origin: Shandong, China

Certification: ISO CE

Minimum Order Quantity: 1

Price: >30000USD

Packaging Details: Wooden box

Delivery Time: 50-60 days

Payment Terms: 30%+70%

Supply Ability: 500 sets per year

Number Of Rotors: 1-3

Total Power Kw: <150kW

Power Supply: 220V/380V

Operation Mode: Automatic

Fluxing Size: Less Than 5 Mm

Keywords: Molten Aluminium Degassing, Hydrogen Removal

Support and Services:

The Product Technical Support and Services for the Rotary Degassing Unit include installation assistance, troubleshooting guidance, and maintenance recommendations. Our team of experts is available to provide comprehensive training on using the unit effectively and maximizing its performance. Additionally, we offer ongoing support to address any issues that may arise with the unit and ensure smooth operations.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!