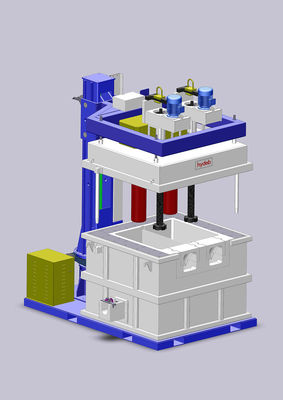

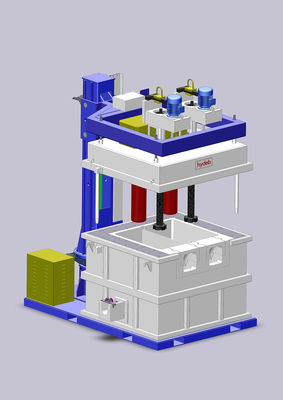

Product Description:

The Rotary Degassing Unit is a highly efficient and advanced system designed for the degassing of molten aluminium, ensuring superior quality and purity. With a remarkable degassing efficiency of 60%, this unit excels in removing impurities from the molten aluminium, resulting in exceptional final product quality.

One of the key features of this Rotary Degassing Unit is its shaft material, which is made of high-quality graphite. Graphite is known for its excellent resistance to high temperatures and corrosive environments, making it an ideal choice for handling molten aluminium. The use of graphite ensures durability and reliability, enhancing the overall performance of the degassing unit.

Another notable attribute of this degassing unit is its adjustable degassing time range of 0 to 99, providing flexibility and precision in the degassing process. The adjustable degassing time allows for fine-tuning based on specific requirements, enabling optimal degassing results for different types of molten aluminium compositions.

When it comes to dimensions, the Rotary Degassing Unit boasts a compact and space-efficient design, with dimensions measuring 1500×1500×1800mm. This compact size makes it suitable for various industrial settings, allowing for easy installation and integration into existing production setups.

Enhancing the operational efficiency and control capabilities of the Rotary Degassing Unit is its advanced control system utilizing Programmable Logic Controller (PLC) technology. The PLC control ensures precise and automated operation of the degassing unit, enabling seamless integration with other production processes and providing real-time monitoring and adjustment functionalities.

Features:

-

Product Name: Rotary Degassing Unit

-

Operation Mode: Automatic

-

Total Power Kw: <150kW

-

Degassing Efficiency: 60%

-

Power Supply: 220V/380V

-

Lifted: By Crane

Technical Parameters:

|

Degassing Efficiency

|

60%

|

|

Degassing Time

|

0~99 Adjustable

|

|

Frequency Hz

|

50Hz

|

|

Rotating Speed

|

100-500 Rpm

|

|

Operation Mode

|

Automatic

|

|

Fluxing Size

|

Less Than 5 Mm

|

|

Lifted

|

By Crane

|

|

Model

|

BDU

|

|

Power Supply Phases

|

Three-phase Four-wire

|

|

Power Supply

|

220V/380V

|

Applications:

Hydeb's BDU Rotary Degassing Unit is a high-quality product designed for various application occasions and scenarios in the metal casting industry. With its innovative features and reliable performance, this in-line Rotary Degassing Unit is highly versatile and suitable for a wide range of casting processes.

One of the primary application scenarios for the Hydeb BDU Rotary Degassing Unit is in foundries and casting facilities where metal quality is of utmost importance. The unit's efficient degassing process, with a degassing efficiency of 60%, ensures the removal of impurities such as hydrogen and other gases from molten metal, resulting in superior casting quality.

Furthermore, the automatic operation mode and PLC control system of the Rotary Degassing Unit make it ideal for use in high-volume production environments. The unit's ability to operate at a frequency of 50Hz ensures consistent and reliable performance, meeting the demanding requirements of modern metal casting processes.

Whether it is in the production of automotive parts, aerospace components, or industrial machinery, the Hydeb BDU Rotary Degassing Unit excels in enhancing the overall quality and integrity of cast metal products. Its ISO CE certification guarantees compliance with international quality standards, giving customers peace of mind regarding product reliability and performance.

With a minimum order quantity of just 1 unit and a price exceeding $30,000 USD, the Hydeb BDU Rotary Degassing Unit offers a cost-effective solution for small to large-scale metal casting operations. The unit is carefully packaged in wooden boxes for secure transportation and has a delivery time of 50-60 days, ensuring prompt availability for customers.

In addition to its exceptional performance, the Hydeb BDU Rotary Degassing Unit boasts a supply ability of 500 sets per year, making it a reliable choice for businesses with varying production needs. Its robust construction and efficient degassing capabilities make it a valuable asset in the metal casting industry.

Customization:

Product Customization Services for the Rotary Degassing Unit:

- Brand Name: Hydeb

- Model Number: BDU

- Place of Origin: Shandong, China

- Certification: ISO CE

- Minimum Order Quantity: 1

- Price: >30000USD

- Packaging Details: Wooden box

- Delivery Time: 50-60 days

- Payment Terms: 30%+70%

- Supply Ability: 500 sets per year

- Fluxing Size: Less Than 5 Mm

- Lifted: By Crane

- Shaft Material: Graphite

- Total Power Kw: <150kW

- Power Supply: 220V/380V

Key Features: Alkali Removal, Molten Aluminium Degassing, Molten Aluminium

Support and Services:

The Rotary Degassing Unit is a high-performance product designed to effectively remove dissolved gases from molten metal, ensuring superior casting quality. Our Product Technical Support team is dedicated to providing comprehensive assistance with installation, operation, and troubleshooting of the unit to optimize its performance.

In addition, our Services team offers maintenance plans, training programs, and on-site support to help maximize the efficiency and longevity of your Rotary Degassing Unit. We are committed to ensuring that your equipment operates at its peak performance to meet your production needs.

Packing and Shipping:

Product Name: Rotary Degassing Unit

Description: The Rotary Degassing Unit efficiently removes gases from molten metal to ensure high-quality casting results.

Package Contents:

- Rotary Degassing Unit

- Instruction Manual

- Safety Guidelines

Product Dimensions:

- Length: 24 inches

- Width: 18 inches

- Height: 12 inches

Shipping Information:

- Shipping Method: Standard Ground Shipping

- Shipping Cost: Calculated at checkout

- Estimated Delivery Time: 3-5 business days

FAQ:

Q: What is the brand name of the Rotary Degassing Unit?

A: The brand name is Hydeb.

Q: Where is the Rotary Degassing Unit manufactured?

A: The product is manufactured in Shandong, China.

Q: What certifications does the Rotary Degassing Unit have?

A: The product is certified with ISO and CE.

Q: What is the minimum order quantity for the Rotary Degassing Unit?

A: The minimum order quantity is 1 unit.

Q: What are the packaging details for the Rotary Degassing Unit?

A: The product is packaged in wooden boxes.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!