Product Description:

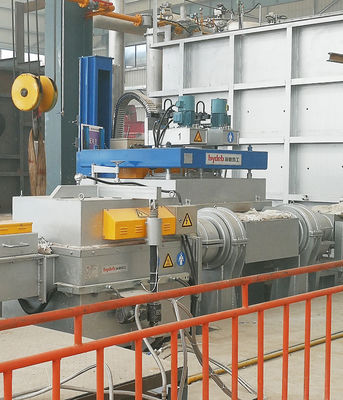

The Rotary Degassing Unit is a state-of-the-art piece of equipment designed to efficiently remove impurities from molten metal in the casting process. This advanced system operates at a power supply of 380V/50Hz, providing the necessary energy for optimal performance.

With a maximum working temperature of 1200°C, the Rotary Degassing Unit can effectively handle high-temperature applications, ensuring thorough degassing of the molten metal to achieve the desired quality and properties in the final product.

One of the key features of the Rotary Degassing Unit is its versatility in gas type usage. Whether utilizing Argon, Nitrogen, or a mixed gas, this unit is capable of accommodating various gas types to suit specific process requirements and metal compositions, allowing for flexibility and customization in operation.

Operating at a vacuum degree of ≤10 Pa, the Rotary Degassing Unit ensures a controlled environment conducive to efficient degassing and impurity removal. By creating a vacuum within the degassing chamber, the system effectively extracts unwanted gases and impurities from the molten metal, resulting in a cleaner and higher-quality end product.

Furthermore, the Rotary Degassing Unit boasts a maximum working pressure of 0.1 MPa, providing the necessary stability and reliability during operation. This ensures consistent performance and safety in handling molten metal, contributing to a smooth and efficient casting process.

Whether used as a standalone Rotary Degassing Box or integrated as an in-line Rotary Degassing Unit within a larger production system, this equipment plays a crucial role in enhancing the quality and integrity of cast metal products. With its advanced capabilities in impurity removal and degassing, the Rotary Degassing Unit is a valuable asset for industries requiring precision and excellence in metal casting processes.

Features:

- Product Name: Rotary Degassing Unit

- Rotating Speed: 0-100 Rpm

- Cooling Water Pressure: 0.2-0.4 MPa

- Lifted: By Crane

- Gas Outlet: 1/4 Inch

- Max. Working Pressure: 0.1 MPa

Technical Parameters:

| Capacity |

100 Kg |

| Max. Working Pressure |

0.1 MPa |

| Control |

PLC |

| Lifted |

By Crane |

| Shaft Material |

Graphite |

| Power Supply |

380V/50Hz |

| Gas Flow Rate |

0-10 L/min |

| Model |

RDG-100 |

| Gas Outlet |

1/4 Inch |

| Max. Working Temperature |

1200°C |

Applications:

Hydeb's BDU Rotary Degassing Unit is a versatile and efficient tool designed for various product application occasions and scenarios. With its advanced features and specifications, this product is suitable for a wide range of industries and purposes.

One common application scenario for the BDU Rotary Degassing Unit is in the aluminum casting industry. The unit's rotor degassing box is ideal for removing hydrogen and other impurities from molten aluminum, ensuring high-quality castings with improved mechanical properties. Its in-line design allows for seamless integration into existing casting processes, making it a valuable tool for foundries and metalworking facilities.

Another key application occasion for the BDU Rotary Degassing Unit is in the automotive manufacturing sector. By utilizing the unit's advanced degassing technology, automotive manufacturers can enhance the quality and performance of their aluminum components, such as engine blocks and cylinder heads. The unit's graphite shaft material and precise gas flow rate control make it a reliable solution for achieving consistent results in high-volume production environments.

Furthermore, the BDU Rotary Degassing Unit is well-suited for use in aerospace and marine engineering applications. Its ISO CE certification ensures compliance with industry standards, making it a trusted choice for critical casting processes where quality and reliability are paramount. The unit's adjustable degassing time and gas outlet specifications provide flexibility for addressing a variety of casting challenges in these demanding sectors.

Whether it's for small-scale batch production or large-scale manufacturing operations, the BDU Rotary Degassing Unit offers a minimum order quantity of 1 unit and a competitive price point exceeding $30,000 USD. Each unit is carefully packaged in a wooden box for safe transportation and delivered within 50-60 days of order placement. With payment terms of 30% upfront and 70% upon delivery, customers can easily acquire this high-quality product from its country of origin, China.

With a supply ability of 500 sets per year and compatible power supply requirements of 380V/50Hz, the BDU Rotary Degassing Unit is a reliable and efficient solution for various degassing applications across different industries. Whether it's for enhancing casting quality, improving material properties, or increasing production efficiency, this innovative product from Hydeb is designed to meet the diverse needs of modern manufacturing processes.

Customization:

Product Customization Services for the Rotary Degassing Unit:

- Brand Name: Hydeb

- Model Number: BDU

- Place Of Origin: China

- Certification: ISO CE

- Minimum Order Quantity: 1

- Price: >30000USD

- Packaging Details: Wooden Box

- Delivery Time: 50-60 Days

- Payment Terms: 30%+70%

- Supply Ability: 500 Sets Per Year

- Control: PLC

- Capacity: 100 Kg

- Lifted: By Crane

- Max. Working Temperature: 1200°C

- Power Supply: 380V/50Hz

Support and Services:

The Product Technical Support and Services for the Rotary Degassing Unit include:

- Initial installation assistance

- Troubleshooting guidance

- Regular maintenance recommendations

- On-site repair services if needed

- Technical training for operators

Packing and Shipping:

Product Packaging:

The Rotary Degassing Unit is carefully packaged in a durable cardboard box with protective foam inserts to ensure safe transportation and delivery.

Shipping Information:

We offer fast and reliable shipping services for the Rotary Degassing Unit. The product will be shipped within 1-2 business days after placing your order. Shipping times may vary depending on your location.

FAQ:

Q: What is the brand name of the Rotary Degassing Unit?

A: The brand name is Hydeb.

Q: Where is the Rotary Degassing Unit manufactured?

A: The Rotary Degassing Unit is manufactured in China.

Q: What certifications does the Rotary Degassing Unit have?

A: The Rotary Degassing Unit is certified with ISO and CE.

Q: What is the minimum order quantity for the Rotary Degassing Unit?

A: The minimum order quantity is 1 unit.

Q: What are the payment terms for purchasing the Rotary Degassing Unit?

A: The payment terms are 30% deposit and 70% upon delivery.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!