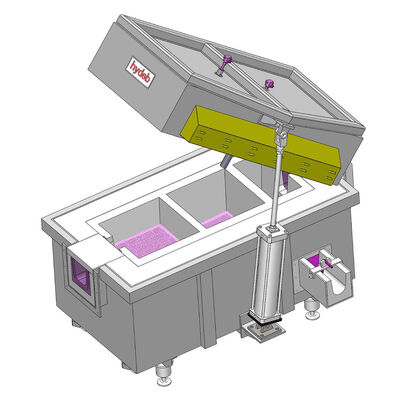

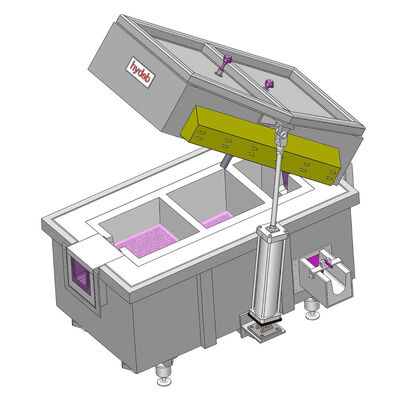

Product Description:

The Filtration Box is an essential component designed specifically for the aluminum smelting and casting industry, providing efficient and reliable mechanical filtration to ensure the highest quality of molten aluminum. Engineered to integrate seamlessly into aluminum smelting and casting production line integration, this filtration box plays a crucial role in removing impurities and inclusions from molten aluminum before it proceeds to the casting process, thereby enhancing the overall quality and integrity of the final product.

At the core of the Filtration Box's functionality is its mechanical filtration type, which utilizes a specially designed filter plate material to trap and separate unwanted particles from the molten aluminum. The filter plate material is selected for its excellent heat resistance and durability, ensuring consistent performance even under the extreme conditions present in aluminum smelting and casting operations. With a plate size of 15 inches, the filtration box offers a substantial filtration surface area, allowing for high throughput while maintaining effective removal of contaminants.

One of the standout features of this Filtration Box is its ease of maintenance, which is a critical factor in maintaining uninterrupted production and minimizing downtime. The recommended maintenance interval for the unit is every 6 months, ensuring that the filter plate material and the overall filtration system remain in optimal condition. Regular maintenance helps to sustain filtration efficiency, prolong the service life of the filtration box, and reduce operational costs by preventing the buildup of debris and potential blockages.

Durability and reliability are paramount in aluminum smelting and casting environments, and this Filtration Box is designed to meet those demands. Backed by an 18-month warranty time, the product assures users of its long-term performance and quality. This warranty period reflects the manufacturer’s confidence in the filtration box's construction and the robustness of the filter plate material used, providing peace of mind to operators and plant managers alike.

Incorporating the Filtration Box into an aluminum smelting and casting production line integration strategy not only improves the cleanliness of the molten aluminum but also contributes to enhanced casting quality, reduced defects, and improved mechanical properties of the final aluminum products. This makes the filtration box an indispensable tool for foundries and smelting facilities aiming to optimize their production processes and meet stringent quality standards.

Overall, the Filtration Box represents a high-performance, reliable solution tailored for the demanding requirements of the aluminum industry. Its mechanical filtration type, combined with a robust 15-inch filter plate material, ensures effective filtration of molten aluminum. With streamlined maintenance every 6 months and a comprehensive 18-month warranty, this product offers a valuable investment for any aluminum smelting and casting operation seeking to enhance product quality and operational efficiency.

Features:

-

Product Name: Filtration Box

-

Power: 30KW for robust performance

-

Filtration Type: Mechanical filtration for effective particle removal

-

Capacity: 1 Gallon

-

Plate Mesh: 60 PPI for fine filtration

-

Inlet Diameter: 50 mm to accommodate high flow rates

-

High efficiency filtration technology ensuring optimal purity

-

Fluid dynamics design for enhanced flow and reduced pressure drop

-

Plate filter box configuration for easy maintenance and durability

Technical Parameters:

|

Capacity

|

1 Gallon

|

|

Filter Media

|

Activated Carbon

|

|

Filtration Precision

|

50 Mesh

|

|

Function

|

Molten Aluminium Filtration Box

|

|

Material

|

Stainless Steel

|

|

Filtration Type

|

Mechanical

|

|

Maximum Pressure

|

Depends On Size And Material

|

|

Plate Mesh

|

60 PPI

|

|

Warranty Time

|

18 Months

|

|

Size

|

12 Inches

|

Applications:

The Hydeb Filtration Box, model number CFB, is a premium filtration solution originating from China, designed to meet the highest industry standards with ISO and CE certifications. Constructed from durable stainless steel, this filtration box ensures long-lasting performance and resistance to corrosion, making it ideal for a variety of demanding filtration applications. Its robust filter plate material, combined with precise casting process control, guarantees exceptional filtration efficiency, effectively removing impurities with a filtration precision of 50 mesh.

With a filtration capacity of 1 gallon and utilizing activated carbon as its filter media, the Hydeb CFB Filtration Box offers superior mechanical filtration suitable for both industrial and laboratory environments. This product is especially valuable in scenarios where high purity and cleanliness are critical, such as chemical processing, pharmaceutical manufacturing, water treatment plants, and food and beverage production. Its ability to efficiently filter out contaminants ensures that the final product meets stringent quality standards.

Due to its sophisticated design and manufacturing process, the Hydeb Filtration Box is ideal for applications requiring consistent and reliable filtration performance. The casting process control used during its production ensures uniformity and precision of the filter plates, which directly contributes to enhanced filtration efficiency and operational stability. This makes it highly suitable for research laboratories, pilot plants, and small-scale production units where precise filtration is crucial.

The packaging details include a sturdy wooden box, providing secure transportation and protection during delivery, which typically takes 50-60 days. With a minimum order quantity of just one set and a price exceeding 5000 USD per set, the Hydeb CFB Filtration Box represents a high-value investment for organizations seeking top-tier filtration solutions. Payment terms are flexible, requiring a 30% deposit with the remaining 70% payable upon delivery.

With a supply ability of 300 sets per year, the Hydeb Filtration Box meets the demands of customers who require reliable filtration equipment for various occasions and scenarios. Whether used in industrial production lines, scientific research, or environmental monitoring, this filtration box stands out for its exceptional filter plate material, outstanding filtration efficiency, and meticulous casting process control, ensuring that every filtration task is performed with precision and reliability.

Customization:

Hydeb offers customized Filtration Box products under the model number CFB, designed specifically for metal melt purification in aluminum alloy smelting processes. Manufactured in China and certified with ISO and CE, this filtration box ensures high-quality performance for casting defect prevention.

The product features mechanical filtration with a plate mesh of 60 PPI and an inlet diameter of 50 mm, powered by a 30KW unit to provide efficient and reliable filtration. Maintenance is recommended every 6 months to maintain optimal functionality.

Our Filtration Box comes packaged securely in a wooden box and is available with a minimum order quantity of just 1 set. Priced above 5000 USD per set, it offers excellent value given its supply ability of 300 sets per year.

Delivery time for customized orders is between 50-60 days, with payment terms set at 30% upfront and 70% upon delivery. Trust Hydeb to deliver superior filtration solutions that enhance aluminum alloy smelting quality and prevent casting defects effectively.

Support and Services:

Our Filtration Box product is designed to provide efficient and reliable filtration solutions for various applications. For technical support, please ensure you have the product model number and serial number available when seeking assistance. Our technical team is equipped to help with installation guidance, troubleshooting, maintenance procedures, and performance optimization.

We recommend regular maintenance of the Filtration Box to ensure optimal performance, including routine filter replacement and system inspections. Detailed maintenance instructions are provided in the user manual, which should be consulted before performing any service tasks.

For service and repairs, only authorized technicians should handle the Filtration Box to maintain product integrity and warranty coverage. Using genuine replacement parts is essential to preserve the quality and reliability of the filtration system.

Additional resources such as FAQs, troubleshooting guides, and product documentation are available to assist users in resolving common issues independently. For complex problems or technical inquiries, our support team is ready to provide expert assistance.

Packing and Shipping:

Product Packaging:

The Filtration Box is securely packaged in a durable, eco-friendly cardboard box designed to protect the product during transit. Inside, the filtration components are cushioned with recyclable foam inserts to prevent movement and damage. Each box includes a user manual and warranty information, ensuring a complete and satisfactory unboxing experience.

Shipping:

We offer fast and reliable shipping options worldwide. The Filtration Box is shipped via trusted carriers with tracking available for all orders. Standard shipping typically takes 5-7 business days, while expedited options are available for quicker delivery. All orders are carefully inspected and packed to guarantee safe arrival at your doorstep.

FAQ:

Q1: What is the brand and model number of the Filtration Box?

A1: The Filtration Box is branded Hydeb and the model number is CFB.

Q2: Where is the Filtration Box manufactured?

A2: The Filtration Box is made in China.

Q3: What certifications does the Filtration Box have?

A3: The Filtration Box is certified with ISO and CE.

Q4: What is the minimum order quantity and price for the Filtration Box?

A4: The minimum order quantity is 1 set, and the price is greater than 5000 USD per set.

Q5: How is the Filtration Box packaged and what is the delivery time?

A5: The Filtration Box is packaged in a wooden box, and the delivery time is approximately 50-60 days.

Q6: What are the payment terms and supply ability for the Filtration Box?

A6: The payment terms are 30% in advance and 70% before delivery. The supply ability is 300 sets per year.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!