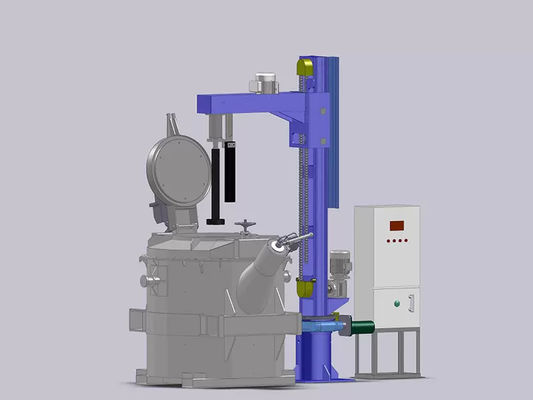

Product Description:

The Aluminum Degassing Machine is known for its high efficiency and reliability. The machine is capable of achieving a refined gas purity of ≥99.996%, which is one of the highest in the market. This level of purity ensures that the final product meets the required standards and is of high quality.

The refining degassing time of the Aluminum Degassing Machine is adjustable within the range of 0 to 99 minutes. This feature allows for flexibility in the degassing process, depending on the specific requirements of the aluminum alloy being produced.

The flow rate of the machine is adjustable and can range from 0.5 to 3 m3/h for a single rotor. This feature allows for the adjustment of the degassing rate, which can be optimized for specific applications. The graphite rotor speed can also be adjusted within the range of 0 to 600 r/min.

The Aluminum Degassing Machine is designed to operate at a voltage of 380±10%, which is a standard voltage in most industrial applications. The machine is also designed to be easy to operate and maintain, which makes it an ideal choice for aluminum foundries.

The Aluminum Degassing Machine is an essential component of any aluminum foundry that produces high-quality aluminum alloys. This product is an ideal choice for companies that require a reliable and efficient degassing machine that can deliver high-purity refined gas. If you are looking for an Aluminium Alloy Degassing Product, the Aluminum Degassing Machine is the perfect choice for you.

Features:

- Product Name: Aluminum Degassing Machine

- Refined gas Purity (%): ≥99.996

- Overall machine weight: 3000KG

- Normal service life of shaft and rotor: 1 Month

- Frequency Hz: 50

- Graphite rotor speed r/min: 0-600

Keywords: Industrial Nitrogen Degassing Machine, Aluminum Degassing Rotor Product, Inline Rotary Degassing Unit Casting

Technical Parameters:

| Product Name: |

Aluminum Degassing Melting Furnace |

| Product Type: |

Online Degassing Liquid System |

| Degasser Type: |

Degasser Alumina Product |

| Total Power KW: |

Less than 5 |

| O2ppm: |

Less than or equal to 5 |

| Refined Gas Purity (%): |

Greater than or equal to 99.996 |

| Frequency Hz: |

50 |

| Normal Service Life of Shaft and Rotor: |

1 Month |

| Flow Rate (single rotor) m3/h: |

0.5~3 (Adjustable) |

| Working Liquid Level in Degassing Tank: |

Greater than or equal to 250 |

| Graphite Rotor Speed r/min: |

0-600 |

| Flow Rate m3/h: |

Greater than or equal to 0.5 |

| Pressure MPa: |

0.1-0.6 (Adjustable) |

Applications:

One of the main applications of the HYDEB HDDL-IV is in the production of aluminum castings. The machine can be used for degassing and refining the aluminum liquid, which results in high-quality products with improved mechanical properties. The machine is suitable for both small and large-scale casting operations, and it can be used for different types of castings, such as automotive parts, aerospace components, and consumer goods.

The HYDEB HDDL-IV can also be used in the recycling of aluminum scrap. The machine can remove impurities and gases from the molten aluminum, allowing the recycled material to be used in the production of high-quality castings. This makes the machine an ideal choice for companies that specialize in aluminum recycling.

Another application of the HYDEB HDDL-IV is in the production of aluminum alloys. The machine can be used for degassing and refining the aluminum alloy, which results in improved mechanical properties and better casting performance. The machine is suitable for different types of aluminum alloys, such as 2000, 5000, and 7000 series.

The HYDEB HDDL-IV can be used in various scenarios, such as in foundries, aluminum smelters, and recycling facilities. The machine is easy to operate and maintain, and it can be integrated into existing production lines without major modifications. The machine is also certified with ISO and CE, ensuring that it meets international quality and safety standards.

The HYDEB HDDL-IV has a minimum order quantity of 1, and it is priced at >1000USD/set. The machine is packaged in wooden boxes and delivered within 50-60 days. The payment terms are 30%+70%, and the supply ability is 300 sets per year. The machine has a graphite rotor speed of 0-600 r/min, a dew point of <-69℃, a maximum aluminum liquid processing volume of 25 t/h, a refined gas purity of ≥99.996%, and a frequency of 50 Hz.

Customization:

Customize your Nitrogen Degassing Machine with HYDEB's Product Customization Services for the HDDL-IV model. Our Degasser Alumina Product is proudly made in Jinan, China, and has ISO CE certification. With a minimum order quantity of 1 and a price of >1000USD/set, the product is packaged in wooden boxes and has a delivery time of 50-60 days. Our payment terms are 30%+70%, and we can supply up to 300 sets per year.

The normal service life of the box lining is ≥12 Months, while the voltage V is 380±10%. The normal service life of the shaft and rotor is 1 Month, with a Dew point ℃ of <-69 and O2ppm of ≤5. Contact us to customize your Degassing Aluminum Casting Product to meet your specific needs.

Support and Services:

Our Aluminum Degassing Machine is designed to remove hydrogen gas and other impurities from molten aluminum to improve the quality and properties of the final product. We offer comprehensive technical support and services to ensure that our customers get the most out of their degassing machine. Our team of experts is available to provide guidance and assistance with installation, operation, maintenance, and troubleshooting of the machine. We also offer training programs to help operators and maintenance personnel become familiar with the machine and optimize its performance. In addition, we provide spare parts and repair services to minimize downtime and keep the machine running smoothly. Contact us for more information on our technical support and services.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!