Product Description:

The machine is designed to operate at a voltage of 380±10%, which ensures stable and consistent performance. The Normal service life of box lining is ≥12 Months, which means that the machine can be used for a long time without the need for frequent maintenance. Additionally, the overall machine weight is 3000KG, which makes it easy to move around and install in different locations.

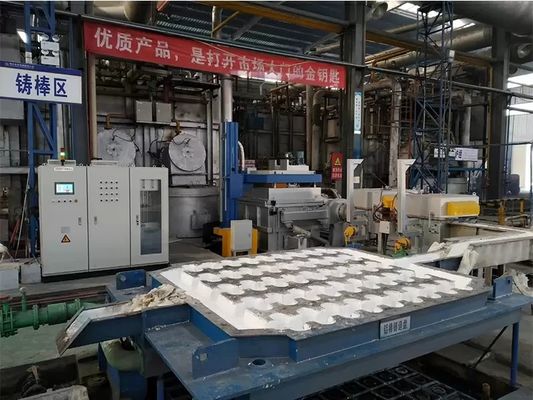

The Inline Rotary Degassing Unitcasting is perfect for use in foundries and other industrial settings where aluminum alloys are cast. It is easy to use, and its compact design ensures that it can fit in tight spaces without compromising its performance. The machine is also built to last, with high-quality materials that can withstand harsh operating conditions.

Overall, the Aluminum Degassing Machine is a reliable and efficient solution for degassing aluminum alloys. Its adjustable pressure system, four Degassing Rotor Aluminum, Normal service life of box lining, and compact design make it an excellent choice for industrial applications. Whether you are in the automotive, aerospace, or construction industry, this machine will help you produce high-quality aluminum alloys that meet your specific needs.

Features:

- Product Name: Aluminum Degassing Machine

- Refining degassing time min: 0~99

- Frequency Hz: 50

- Refined gas Purity (%): ≥99.996

- Normal service life of shaft and rotor: 1 Month

- voltage V: 380±10%

Keywords: Inline Rotary Degassing Unit Casting, Degassing Liquid Machine Equipment, Industrial Nitrogen Degassing Machine

Technical Parameters:

| Frequency Hz |

50 |

| Moisture (ppm) |

≤3 |

| Dew point ℃ |

<-69 |

| O2ppm |

≤5 |

| Flow rate m3/h |

≥0.5 |

| Refining degassing time min |

0~99 |

| Number of rotors |

4 |

| Graphite rotor speed r/min |

0-600 |

| Normal service life of box lining |

≥12 Months |

| Overall machine weight |

3000KG |

This is a table of technical parameters for the Degassing Liquid Machine Equipment, which is used for Degassing Aluminium Foundry and producing Degasser Alumina Product.

Applications:

The HYDEB HDDL-IV Aluminum Degassing Machine is used in various occasions and scenarios. It is used in the production of aluminum castings in industries such as automotive, aerospace, and construction. This machine is suitable for large-scale aluminum casting production and is used for refining the gas purity to a level of ≥99.996%. This ensures that the aluminum casting products produced are of high quality and meet industry standards.

The HYDEB HDDL-IV Aluminum Degassing Machine is specifically designed for the degassing of alumina products. It has a graphite rotor speed range of 0-600 r/min and is used to remove hydrogen and other gases from the molten aluminum to improve the quality of the aluminum casting products produced. The HYDEB HDDL-IV Aluminum Degassing Machine has three phases and a moisture level of ≤3 ppm. Its pressure can be adjusted between 0.1-0.6 MPa to suit different production needs.

Customization:

Support and Services:

The Aluminum Degassing Machine is a complex piece of equipment used in the aluminum casting industry. It is designed to remove hydrogen and other impurities from molten aluminum, resulting in higher quality castings. To ensure optimal performance and longevity of the machine, it is recommended that regular maintenance and inspections are conducted by trained technicians. In addition, technical support is available for any issues or questions that may arise during operation. Our team of experts is dedicated to providing prompt and effective solutions to ensure minimal downtime and maximum productivity. We also offer training services for operators and maintenance personnel to ensure proper operation and maintenance of the machine.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!