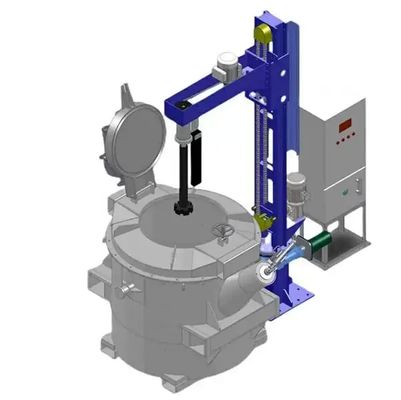

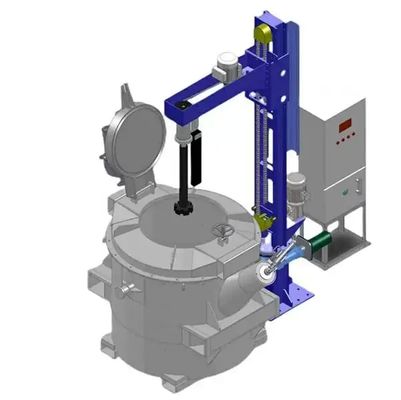

Product Description:

With a flow rate of at least 0.5 m3/h, our machine can handle a flow range of 15 to 30 L/min, which is adjustable depending on your specific needs. The inline degassing process ensures that the aluminum is free from harmful gases and impurities, resulting in a high-quality end product with refined gas purity of at least 99.996 percent.

Our Aluminum Foundry Degasser is built with a total power of 3KW, making it a reliable and efficient machine for your aluminum casting needs. The compact design allows for easy installation and operation, while the durable construction ensures long-lasting performance.

Whether you are in the automotive, aerospace, or construction industry, our Aluminum Foundry Degasser is the perfect solution for your aluminum casting needs. With its fast and efficient inline degassing process, you can rest assured that your end product will have the highest quality and purity possible.

Features:

◆ Able to remove gases (mainly hydrogen) and oxides from the molten aluminum more effectively. The equipment has the advantages of both gas refining and flux-refining. After rotary injection, the hydrogen concentration in molten aluminum alloys will be reduced below 0.1ml/100g, the pinhole degree will reach up to level 1, the density will be less than 1, and a stable effect will be achieved.

◆ Low metal loss. After proper flux-refining, there is less dross on the melt surface and the dross is loose. The metal is rarely encased and little metal is taken out during slag removal.

◆ Low refining agent consumption and stable feeding.

◆ Equipped with an anti-falling mechanism, a refining agent material level measuring and an air channel leakage detector.

◆ Multiple technological processes can be executed. When used with different functions of fluxes, it can be used for high-efficiency modification, degassing and slag removal.

◆ The rotor bearing is a high-temperature bearing, not needing to be air-cooled. The spindle can work without stop at a high temperature of 200°C.

◆ Automatic operation, site working conditions are significantly improved.

Technical Parameters:

| Technical Parameter | Value |

|---|

| Pressure MPa | 0.1-0.6 Adjustable |

| Flow rate L/min | ≥0.4 |

| Total power KW | 3 |

| Number of Phases | 3 |

| Moisture (ppm) | ≤3 |

| Refining degassing time min | 0~99 |

| Graphite rotor speed r/min | 100-600 |

| O2ppm | ≤5 |

| Flow rate L/min | 15~30 Adjustable |

| Flow rate m3/h | ≥0.5 |

This is the technical parameter table for the Inline Rotary Degassing Unitcasting, Degasser Alumina Product.

Applications:

The HYDEB XCP230-1 is suitable for a wide range of applications in the aluminum foundry industry. It is commonly used in the production of automotive parts, aerospace components, and construction materials. The degassing liquid machine is also suitable for other industries that require the removal of impurities from molten metals.

The equipment has a minimum order quantity of 1 and is priced at more than $1000 per set. The packaging details include a wooden box, and the delivery time is 50-60 days. The payment terms are 30%+70%, and the supply ability is 300 sets per year. The HYDEB XCP230-1 has a flow rate of m3/h: ≥0.5, graphite rotor speed r/min: 100-600, pressure MPa: 0.1-0.6 adjustable, total power KW: 3, and refined gas purity (%): ≥99.996.

The HYDEB XCP230-1 is ideal for aluminum foundries that require a reliable and efficient degassing machine. The equipment is designed to remove impurities from molten aluminum, which results in high-quality aluminum products. The machine is easy to operate, and it is built to last. It is suitable for both small and large-scale aluminum foundries.

In conclusion, if you are looking for an aluminum foundry degasser that is reliable, efficient, and easy to operate, the HYDEB XCP230-1 is an excellent choice. The industrial nitrogen degassing machine is suitable for a wide range of applications in the aluminum foundry industry and other industries that require the removal of impurities from molten metals. Contact us today to place your order.

Customization:

The minimum order quantity for the machine is 1 and the price is set at >1000USD/set. The machine is packaged in a wooden box for secure transportation and has a delivery time of 50-60 days. The payment terms for the product are 30%+70%.

The machine has a supply ability of 300 sets per year and has the following specifications:

- Flow rate m3/h: ≥0.5

- Moisture (ppm): ≤3

- Flow rate L/min: ≥0.4

- Frequency Hz: 50

- Total power KW: 3

Investing in HYDEB's Aluminum Degassing Machine ensures efficient and reliable online degassing of aluminum foundry. Contact us today to avail of our product customization services.

Support and Services:

The Aluminum Degassing Machine is designed and manufactured to provide efficient and high-quality degassing of molten aluminum. Our product technical support and services include:

- Installation and commissioning

- Operator training and education

- Regular maintenance and repairs

- Technical support via phone or email

- Supply of spare parts and consumables

- Upgrades and retrofits

Our team of experts is dedicated to ensuring that your aluminum degassing machine operates at optimal performance and productivity. Contact us for any inquiries or assistance.

Packing and Shipping:

Product Packaging:

- The aluminum degassing machine will be packaged in a sturdy wooden crate to ensure safe transportation.

- The crate will be lined with foam to prevent any damage during transit.

- All necessary components and accessories will be securely packed and labeled for easy identification.

Shipping:

- The aluminum degassing machine will be shipped via a reliable and experienced freight company.

- The shipping cost will be calculated based on the weight and dimensions of the crate.

- The customer will be provided with a tracking number to monitor the shipment's progress.

- The estimated delivery time will depend on the customer's location and shipping method chosen.

FAQ:

Q: What is the brand name of the Aluminum Degassing Machine?

A: The brand name of the Aluminum Degassing Machine is HYDEB.

Q: What is the model number of the Aluminum Degassing Machine?

A: The model number of the Aluminum Degassing Machine is XCP230-1.

Q: Where is the Aluminum Degassing Machine manufactured?

A: The Aluminum Degassing Machine is manufactured in Jinan, China.

Q: What certifications does the Aluminum Degassing Machine have?

A: The Aluminum Degassing Machine has ISO CE certification.

Q: What is the minimum order quantity for the Aluminum Degassing Machine?

A: The minimum order quantity for the Aluminum Degassing Machine is 1.

Q: What is the price range for the Aluminum Degassing Machine?

A: The price range for the Aluminum Degassing Machine is >1000USD/set.

Q: What is the packaging method for the Aluminum Degassing Machine?

A: The Aluminum Degassing Machine is packaged in a wooden box.

Q: How long does it take to deliver the Aluminum Degassing Machine?

A: It takes 50-60 days to deliver the Aluminum Degassing Machine.

Q: What are the payment terms for the Aluminum Degassing Machine?

A: The payment terms for the Aluminum Degassing Machine are 30%+70%.

Q: What is the supply ability of the Aluminum Degassing Machine?

A: The supply ability of the Aluminum Degassing Machine is 300 sets per year.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!