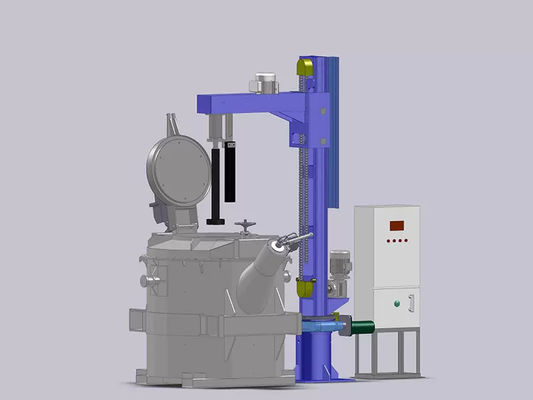

Product Description:

This Aluminum Degassing Rotor Product comes with a high-quality Graphite Degassing Rotor and Shaft that can rotate at a speed of 100-600 r/min. This ensures efficient degassing of the molten aluminum and removal of impurities such as hydrogen gas and oxides. The result is a higher quality, defect-free aluminum alloy that is ideal for use in various applications.

Our Aluminium Alloy Degassing Product is also equipped with an adjustable pressure system that can be set from 0.1-0.6 MPa. This allows for precise control over the degassing process, ensuring optimal results every time. Additionally, this product has three phases and a voltage of 380±10%, making it compatible with a wide range of industrial settings.

With a flow rate of ≥0.4 L/min, our Aluminum Degassing Machine is highly efficient and can handle large volumes of molten aluminum. This makes it perfect for use in high-volume aluminum casting operations.

Investing in our Aluminum Degassing Machine is a smart choice for those who want to improve the quality and purity of their aluminum alloys. With its high-quality Graphite Degassing Rotor and Shaft, adjustable pressure system, and efficient flow rate, this product is a must-have for any serious player in the aluminum casting industry. Order yours today!

Features:

◆ Able to remove gases (mainly hydrogen) and oxides from the molten aluminum more effectively. The equipment has the advantages of both gas refining and flux-refining. After rotary injection, the hydrogen concentration in molten aluminum alloys will be reduced below 0.1ml/100g, the pinhole degree will reach up to level 1, the density will be less than 1, and a stable effect will be achieved.

◆ Low metal loss. After proper flux-refining, there is less dross on the melt surface and the dross is loose. The metal is rarely encased and little metal is taken out during slag removal.

◆ Low refining agent consumption and stable feeding.

◆ Equipped with an anti-falling mechanism, a refining agent material level measuring and an air channel leakage detector.

◆ Multiple technological processes can be executed. When used with different functions of fluxes, it can be used for high-efficiency modification, degassing and slag removal.

◆ The rotor bearing is a high-temperature bearing, not needing to be air-cooled. The spindle can work without stop at a high temperature of 200°C.

◆ Automatic operation, site working conditions are significantly improved.

Technical Parameters:

◆ Refining time: 0~99min

◆ Gas flow for refinement: 12~30NL/min

◆ Inert gas for degassing: N2 or Ar with a purity greater than 99.996%

◆ Gas working pressure: 0.1-0.4MPa

◆ Molten aluminum temperature: 640-850℃

◆ Amount of molten aluminum treated: 200-3000kg

◆ Rotor speed: 0-800r/min (max speed: 1000rpm)

Support and Services:

The Aluminum Degassing Machine is a specialized equipment designed to remove hydrogen and other impurities from molten aluminum. Our product comes with the following technical support and services:

- Installation assistance and training for the machine operators

- Regular maintenance and inspection to ensure optimal performance

- Technical support for any issues that may arise during operation

- Replacement parts and repair services

- Upgrades and customization options to meet specific customer requirements

Our team of experienced engineers and technicians are committed to providing top-notch technical support and services to ensure our customers' satisfaction with the Aluminum Degassing Machine.

Packing and Shipping:

Product Packaging:

- The Aluminum Degassing Machine will be securely packaged in a heavy-duty cardboard box.

- The machine will be wrapped in bubble wrap and other protective materials to prevent any damage during transit.

- Instruction manuals and other necessary documents will be included in the package.

Shipping:

- The product will be shipped within 2 business days of receiving the order.

- We offer free shipping to all locations within the United States.

- International shipping is available at an additional cost. Please contact us for more information.

- Delivery times may vary depending on the destination. Estimated delivery times will be provided upon shipment.

FAQ:

Q1: What is the Brand name of this aluminum degassing machine?

A1: The brand name of this aluminum degassing machine is HYDEB.

Q2: What is the Model Number of this aluminum degassing machine?

A2: The Model Number of this aluminum degassing machine is XCP230-1.

Q3: Where is this aluminum degassing machine manufactured?

A3: This aluminum degassing machine is manufactured in Jinan, China.

Q4: What certifications does this aluminum degassing machine have?

A4: This aluminum degassing machine is certified with ISO CE.

Q5: What is the minimum order quantity for this aluminum degassing machine?

A5: The minimum order quantity for this aluminum degassing machine is 1 set.

Q6: What is the price of this aluminum degassing machine?

A6: The price of this aluminum degassing machine is greater than 1000USD/set.

Q7: What is the packaging detail for this aluminum degassing machine?

A7: This aluminum degassing machine comes in a wooden box.

Q8: What is the delivery time for this aluminum degassing machine?

A8: The delivery time for this aluminum degassing machine is 50-60 days.

Q9: What are the payment terms for this aluminum degassing machine?

A9: The payment terms for this aluminum degassing machine are 30%+70%.

Q10: What is the supply ability for this aluminum degassing machine?

A10: The supply ability for this aluminum degassing machine is 300 sets per year.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!