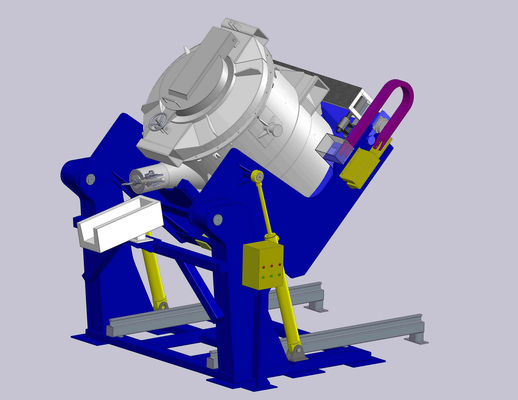

Hydraulic Tilting Device For Transfer Ladles Automatic Molten Aluminum Pouring System With Hydraulic Tilting Cylinder

1. EQUIPMENT APPLICATION

Hydraulic Tilting Device is used for tilting the transfer ladles and pouring out the molten aluminum from the ladles.

2. EQUIPMENT FEATURES

• Easy operation

• Safely pouring out the molten aluminum

• No spare parts

• Tilting angle can be 90 Degree

3. STRUCTURE AND COMPOSITION

---- The equipment is mainly composed of tilting bracket, fixed bracket, tilting cylinder, hydraulic system, electrical control system and other parts. The appearance and related dimensions will be according to the ladle drawing.

---- The device is fixed on the ground in some place in the workshop, with operation buttons by manual on the cabinet.

---- The titling bracket is composed of a chassis, a vertical support, a guide plate, a nozzle positioning card and other parts. It is made of steel plate and section steel after necessary processing and welding, and has sufficient strength. The frame is composed of two parts: the base and the turning frame. The bottom frame is made of welded section steel, with upright braces and guide plates welded on top, and the upright braces are made of section steel and welded with steel plates inside to ensure sufficient support strength.

----- The fixed bracket is composed of vertical support, base and other parts. Both the support and the base are made of profiled steel lined with reinforcing rib plates.

---- The hydraulic system includes hydraulic station, valve block, control oil circuit and other parts. The tilting of the equipment is controlled by an electromagnetic reversing valve. The electronic control system of the hydraulic system needs to use Siemens and Schneider components to ensure the normal operation of the system, and the turning operation adopts the jog method.

---- The tipping system should be safe and reliable with a safety protection system, and hydraulic locks should be used in the hydraulic circuit of the locking cylinder to ensure reliable locking.

---- The tilting oil cylinder adopts a large bore oil cylinder, which has a large bearing capacity, and the oil seal adopts an imported high temperature resistant oil seal.

---- When the cylinder is fully extended, the maximum tilting angle of the tilting bracket is greater than 90 degree. .

---- Hydraulic system design interlock circuit

---- The piston rod of the hydraulic cylinder should have sufficient finish, strength and corrosion resistance. No shaking and no oil leakage during no-load and load. The outer surface of the hydraulic cylinder oil pipe must be treated to prevent high temperature

---- The control cabinet is a self-supporting dust-proof type, and the thickness of the steel plate of the cabinet is not less than 1.2mm.

4. MAIN PARAMETERS

| Items |

Parameters |

Remarks |

| Used for Ladle |

|

According to the ladle capacity and size |

| Transfer ladle Loading Method |

By crane or Forklift |

|

| Tilting Angle |

90 Degree |

|

| Tilting Time |

About 90 S |

|

| Power of Hydraulic System |

|

Depend on the Ladle capacity |

| Power |

Voltage |

380 V, 3P |

|

| Frequency |

50HZ |

|

5. Equipment Pictures

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!