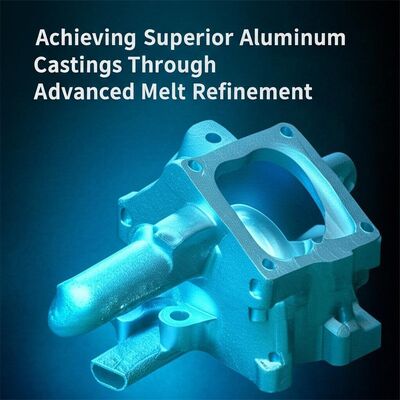

Achieving Superior Aluminum Castings Through Advanced Melt Refinement

Producing high-integrity aluminum castings demands rigorous control over melt purity. Impurities—including dissolved gases, oxides, and non-metallic inclusions—can severely compromise mechanical properties, surface quality, and corrosion resistance. This guide outlines essential purification techniques and their strategic implementation in modern foundry operations.

Eliminating Dissolved Gases for Dense, Sound Castings

Dissolved hydrogen is a primary cause of porosity in solidified aluminum. Proven degassing approaches include:

- Rotary Impeller Degassing: An argon or nitrogen stream is dispersed via a spinning impeller, generating micro-bubbles that efficiently extract hydrogen. Achievable hydrogen levels can fall below 0.1 mL per 100g of aluminum.

- Solid Flux Tablets: Chlorine-based compounds (e.g., hexachloroethane) release cleansing gases upon immersion, removing hydrogen and lifting light inclusions.

- Vacuum Degassing: Employed for premium applications, this process subjects the melt to sub-atmospheric pressure to draw out dissolved gases.

Process Insight: Optimal degassing occurs within the 710-750°C range.

Fluxing: Essential Chemical Cleansing of the Melt

Specialized fluxes enhance metal cleanliness by interacting with impurities:

- Protective Cover Fluxes (e.g., NaCl-KCl blends) shield the melt surface from oxidation.

- Dross Removal Fluxes modify oxide layers for easier skimming.

- Wall-Cleaning Fluxes help remove accumulated deposits from furnace linings.

Key Consideration: Precise flux dosage is critical to avoid introducing additional contaminants.

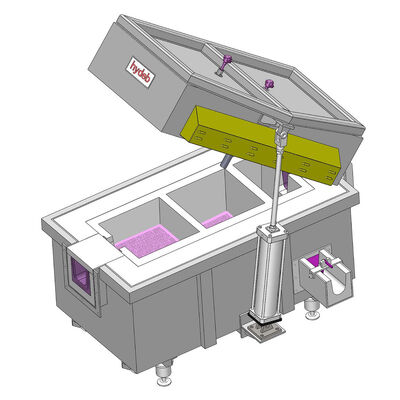

Filtration: Critical Removal of Solid Inclusions

Filters trap oxides, carbides, and other solid particles that act as stress concentrators:

- Ceramic Foam Filters (CFF): With porosity grades from 10 to 60 PPI, they balance inclusion capture with metal throughput.

- Deep-Bed Filter Systems: Used for ultra-high-purity requirements, such as in foil stock production.

- Electromagnetic Filtration: Particularly effective for separating iron-rich intermetallics in conductive alloys.

Selection Guideline: Gravity casting often uses 10-30 PPI filters; finer filters (30-60 PPI) are preferred for low-pressure casting.

Precision Alloying: Tailoring Final Melt Composition

After purification, targeted additions adjust microstructure and properties:

- Grain Refiners (Al-Ti-B) enhance uniformity and strength.

- Modifying Agents (Sr, Na) optimize silicon morphology in Al-Si alloys.

- Iron Neutralizers (Mn, Cr) mitigate the brittle effects of iron impurities.

Final Verification: Spectrochemical analysis before casting confirms alloy specification compliance.

Integrated Purification: Building a Reliable Process

A synergistic approach—combining degassing, flux treatment, and filtration—delivers consistent, high-quality results. Priorities vary by sector: automotive castings focus on hydrogen control, while electronic components demand minimal inclusion counts.

Implementing these refined melt practices allows foundries to achieve repeatable quality, reduce scrap, and meet stringent performance standards.

Seeking to Optimize Your Aluminum Melt Processing?

Our engineering team provides application-specific guidance and tailored purification solutions. Reach out for a technical consultation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!