Product Description:

The Rotary Flux Injector has a minimum cooling time between refining of 20 minutes. This ensures that the machine maintains its efficiency and performance during the refining process. The machine has a refining degassing time of 0 to 99 minutes, which provides a wide range of options for refining aluminum.

The Aluminum liquid temperature range for the Rotary Flux Injector is 680-750℃. This temperature range is ideal for refining aluminum and ensures that the process is efficient and effective. The machine has an aluminum liquid depth range of 600-1100㎜, which provides flexibility in the refining process.

The Rotary Flux Injector is powered by a 380V/220V±10% power supply. This ensures that the machine is reliable and efficient, providing consistent performance during the refining process. The machine is designed to be easy to operate and maintain, making it an ideal choice for aluminum refining.

In summary, the Rotary Flux Injector is an efficient and reliable machine for aluminum refining. It is equipped with an advanced refining system that ensures the aluminum is purified to the highest standards. The machine has a minimum cooling time between refining of 20 minutes, a refining degassing time of 0 to 99 minutes, an Aluminum liquid temperature range of 680-750℃, and an aluminum liquid depth range of 600-1100㎜. The machine is powered by a 380V/220V±10% power supply, making it reliable and efficient. With the Rotary Flux Injector, you can expect exceptional results in your aluminum refining process.

Features:

-

Product Name: Flux Injection Machine

-

Refining flux: Granularity≤3mm

-

Power supply: 380V/220V±10%

-

Maximum flow rate of refining gas: Adjustable From 6~30m3/h

-

Motor power: 300W

-

Aluminum liquid depth range: 600-1100㎜

-

Features:

-

Degassing slag removal and impurity

-

Aluminum refining

-

Rotary Flux Injector

Technical Parameters:

|

Aluminum liquid depth range

|

600-1100㎜

|

|

Maximum flow rate of refining gas

|

Adjustable From 6~30m3/h

|

|

Bucket capacity

|

50L

|

|

Minimum cooling time between refining

|

20min

|

|

Aluminum liquid temperature

|

680-750℃

|

|

Maximum furnace time (including preheating, refining, etc.)

|

90min

|

|

Refining degassing time

|

0~99min

|

|

Power supply

|

380V/220V±10%

|

|

Type of refining gas

|

High-purity Nitrogen Or Argon Gas

|

|

Graphite rotor speed

|

0~400r/min

|

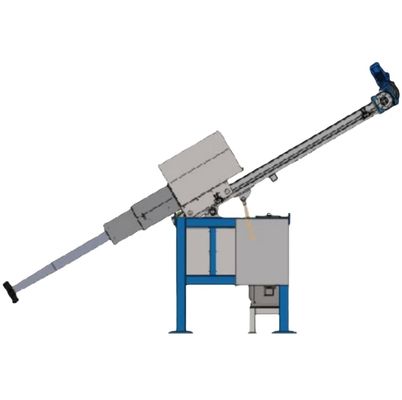

Rotary Flux Injector with rotor for Aluminum refining, degassing and slag removal.

Applications:

The Flux Injection Machine is equipped with a Rotary Flux Injector with rotor, which provides a maximum flow rate of refining gas that is adjustable from 6~30m3/h. The aluminum liquid temperature can be maintained between 680-750℃. The power supply required is 380V/220V±10%. The machine also has a minimum cooling time between refining of 20min, and a refining gas pressure of 0.4~0.6MPa.

The Flux Injection Machine has multiple product application occasions and scenarios. It can be used in aluminum casting plants, die casting plants, and aluminum alloy plants. The machine is highly efficient in removing hydrogen and other impurities from molten aluminum and improving the quality of aluminum products. The machine can be used for refining aluminum alloy, aluminum ingots, and other aluminum products.

The Flux Injection Machine is suitable for large-scale production and can be used in various scenarios. The machine is highly efficient in removing gas and slag from molten aluminum and is an essential tool in the production of high-quality aluminum products. The machine is easy to operate and can be controlled remotely.

The Flux Injection Machine is packaged in a standard exporting package and is easy to ship. The machine is designed to be durable and long-lasting, ensuring that it can be used for many years without any issues. The machine is backed by a warranty and excellent customer support, ensuring that customers can get the help they need when they need it.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!