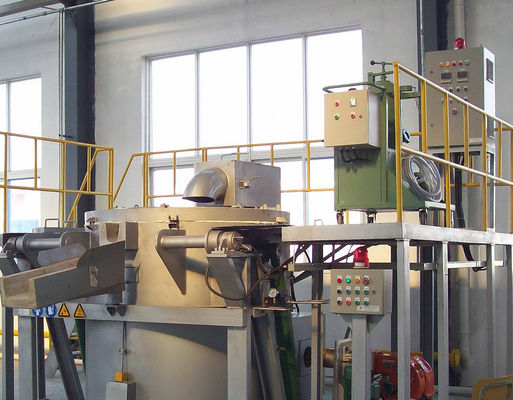

15L Capacity Tank Green Flux Injection Machine for Alumium Alloy Die Casting

Aluminum Alloy Die Casting Injection Fluxing Refining Device

1. Refining Machine Function

This equipment is used for degassing and deslagging of the molten aluminum in static furnace.

2. Refining Machine Features

• Good refining effects. The equipment has the advantages of both gas refining and flux-refining.

• Low consumption of refining agent, and uniform feeding.

• Low metal loss. After proper flux-refining, there is less dross on the melt surface and the dross is loose.

• The metal is rarely encased and little metal is taken out during slag removal.

3. Hydeb Company Profile

-- Established in January 2003, and now has 56 employees

-- Sales of 50 million RMB in 2020

-- Focus on one industry -- "aluminum casting"

-- Has a complete product line of aluminum casting equipment, all products are independent research

and development, manufacturing

-- aluminum melting and holding, transportation, ladle preheating, aluminum liquid refining, aluminum liquid

hydrogen measurement, until aluminum solution aging treatment equipment

4. About Us Hydeb

5. Mainly Parameters For Injection Machine

| Barrel capacity |

15L |

| Refining gas type |

high-purity nitrogen or argon |

| Refining gas pressure |

0.1-0.4MPa |

| Maximum refining gas flow |

300NL/min |

| Flux flow |

0-3000g/min, adjustable |

| Flux size |

10-70 meshes |

6. Types

7. Reference Pictures

8. Delivery

9. RFQ

Q1: I know nothing about this refining machine, what kind of refining machine I should choose?

Very easy. We will email you an inquiry form for making sure your real need. Or just tell us what you want to do

by using this machine, then let us give you perfect solutions and suggestions.

Q2: When I get this refining machine, but I don’t know how to use it. What should I do?

We will send pictures or video and English manual with the machine. If you still have some doubts, we can talk

by Telephone/ Skype / Whatsapp / Weichat/ E-mail.

Q3: If some problems happen to this refining machine during warranty period, what should I do?

We will supply free parts during machine warranty period if machine have some problems (except spare parts).

While we also supply free life long after-sales service. So any doubts, just let us know, we will give you solutions.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!