Product Description:

Rotary Degassing Unit - Furnace Side Refining Equipment for Molten Aluminum Purification

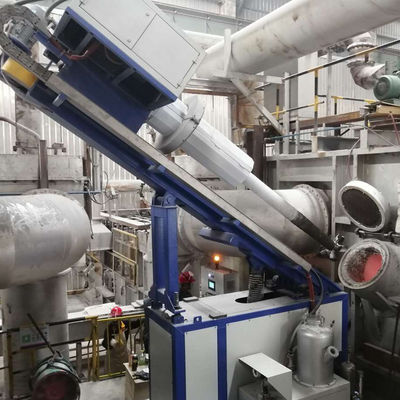

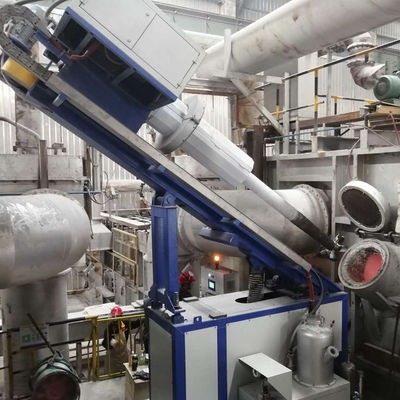

The Rotary Degassing Unit is an advanced and efficient furnace side refining equipment designed for the purification of molten aluminum. It is an essential component of any aluminum production process, ensuring high-quality and reliable production of aluminum products.

Equipped with the latest technology, the Rotary Degassing Unit is capable of removing impurities from molten aluminum with precise control. Its customizable features make it suitable for various types of aluminum production processes, providing improved and enhanced performance.

Frequency Hz: 50Hz

The Rotary Degassing Unit operates at a frequency of 50Hz, ensuring stable and efficient performance. This frequency is ideal for the purification of molten aluminum and helps in achieving high-quality results.

Refined Gas Flow Rate m³/h: Adjustable From 5.7 To 25.5

The refined gas flow rate of the Rotary Degassing Unit is adjustable, ranging from 5.7 to 25.5 m³/h. This feature allows for precise control over the purification process, making it suitable for different production requirements.

Graphite Rotor Speed r/min: 100-400

The graphite rotor speed of the Rotary Degassing Unit can be adjusted from 100 to 400 r/min. This speed range provides flexibility in the purification process, ensuring efficient removal of impurities from molten aluminum.

Rotor Tilt Range mm: 0 To 32°

The rotor tilt range of the Rotary Degassing Unit is from 0 to 32°, allowing for customizable purification settings. This feature enables efficient removal of impurities and ensures high-quality aluminum production.

Total Power kW: <150kW

The Rotary Degassing Unit requires a total power of less than 150kW to operate, making it an energy-efficient option for molten aluminum purification. This not only reduces energy costs but also helps in maintaining a sustainable production process.

The Rotary Degassing Unit is an essential aluminum in-furnace impurity removal equipment, providing efficient and high-quality purification of molten aluminum. Its advanced technology, precise control, and customizable features make it an ideal choice for any aluminum production process. With improved and enhanced performance, the Rotary Degassing Unit is a reliable and efficient solution for purifying molten aluminum.

Features:

- Product Name: Rotary Degassing Unit

- Refined Gas Purity %: ≥99.997

- Rotor Swing Range: 30°

- Refined Gas Flow Rate m³/h: Adjustable From 5.7 To 25.5

- Refinement and Degassing Time min: 0 To 99

- Refined Gas Pressure MPa: Adjustable From 0.1 To 0.6

- Aluminum Smelting Purification Equipment

- Aluminum Furnace Side Refining Equipment

- Aluminum Smelting Purification Equipment

Technical Parameters:

| Product Name |

Rotary Degassing Unit |

| Product Type |

Smelting Purification Equipment |

| Application |

Aluminum Furnace side refining equipment |

| Model Number |

AL-RDU |

| Technical Parameters |

Values |

| Refined Gas Pressure |

Adjustable from 0.1 to 0.6 MPa |

| Rotor Swing Range |

30° |

| Rotor Tilt Range |

0 to 32° mm |

| Refinement and Degassing Time |

0 to 99 min |

| Total Power |

Less than 150 kW |

| Refined Gas Flow Rate |

Adjustable from 5.7 to 25.5 m³/h |

| Refined Gas Purity |

Greater than or equal to 99.997% |

| Power Supply Phases |

Three-phase Four-wire |

| Graphite Rotor Speed |

100-400 r/min |

| Voltage |

380V |

Applications:

Rotary Degassing Unit - Providing High-Quality Aluminum Refining

Brand Name: HYDEB

Model Number: HDR-2xxx

Place of Origin: Jinan, China

Certification: CE ISO9001

Minimum Order Quantity: 1 set

Price: 9998USD/set

Packaging Details: Standard exporting package

Delivery Time: 45 workdays

Payment Terms: L/C, T/T, Western Union, MoneyGram

Supply Ability: 60 sets per year

Product Description

The Rotary Degassing Unit, also known as the HYDEB HDR-2xxx, is a high-quality aluminum refining equipment designed and manufactured in Jinan, China. This product is specifically designed for use in front of furnaces to remove impurities from molten aluminum, ensuring a clean and high-quality end product.

Application

The Rotary Degassing Unit is an essential tool for aluminum production plants, particularly in the refining process. It is used in the aluminum industry to remove impurities from molten aluminum, such as hydrogen, inclusions, and other non-metallic elements. This ensures the production of high-quality and pure aluminum, suitable for use in various industries, including automotive, construction, and aerospace.

Product Features

- Rotor Tilt Range mm: 0 To 32°

- Refinement and Degassing Time min: 0 To 99

- Power Supply Phases: Three-phase Four-wire

- Refined Gas Pressure MPa: Adjustable From 0.1 To 0.6

- Voltage V: 380V

Scene and Scenario

The Rotary Degassing Unit is typically used in the aluminum production process in front of furnaces. It is a crucial step in the production of high-quality aluminum, as it removes impurities and ensures the final product is clean and pure. The machine is operated by trained professionals who monitor the refining and degassing process, ensuring optimal results.

Imagine a scene in an aluminum production plant, where molten aluminum is being poured into the Rotary Degassing Unit. The equipment is set up in front of the furnace, and the operators use the control panel to adjust the rotor tilt, refinement time, and gas pressure according to the specific needs of the production process. The machine hums as it removes impurities from the molten aluminum, creating a clean and pure product.

The Rotary Degassing Unit is also used in the In-Furnace Impurity Removal process, where it removes impurities directly from the furnace. This eliminates the need to transfer molten aluminum to a separate machine, making the production process more efficient and cost-effective.

Conclusion

The Rotary Degassing Unit, branded as HYDEB, is an essential tool in the aluminum refining process. Its advanced features and efficient performance make it a popular choice among aluminum production plants worldwide. With its high-quality and reliable results, it is a must-have for any aluminum production facility. Choose HYDEB's Rotary Degassing Unit and experience the best in aluminum refining technology.

Customization:

HYDEB Rotary Degassing Unit: Your Customized Solution for Aluminum Smelting

Brand Name: HYDEB

Model Number: HDR-2xxx

Place of Origin: Jinan, China

Certification: CE ISO9001

Minimum Order Quantity: 1 set

Price: 9998USD/set

Packaging Details: Standard exporting package

Delivery Time: 45 workdays

Payment Terms: L/C, T/T, Western Union, MoneyGram

Supply Ability: 60 sets per year

Power Supply Phases: Three-phase Four-wire

Frequency Hz: 50Hz

Voltage V: 380V

Rotor Tilt Range mm: 0 To 32°

Total Power kW: <150kW

Customization for Your Specific Needs

At HYDEB, we understand that every aluminum smelting operation is unique and requires a customized solution. That's why we offer a range of customization options for our Rotary Degassing Unit, designed to meet your specific requirements.

Aluminum Furnace Side Refining Equipment

Our Rotary Degassing Unit is designed to provide efficient purification and degassing of molten aluminum in furnace side refining processes. With our customizable options, you can ensure that the unit is tailored to fit seamlessly into your existing aluminum smelting operation.

Aluminum Smelting Purification Equipment

As a crucial step in the aluminum smelting process, purification requires precision and reliability. Our Rotary Degassing Unit can be customized to meet your specific purification needs, helping to improve the overall quality of your aluminum production.

Furnace Side Refining Equipment Customization

Our customization options for the Rotary Degassing Unit include:

- Rotational speed adjustment to fit your specific process requirements

- Customized rotor tilt range, up to 32°, to ensure optimal degassing efficiency

- Adjustable gas flow rate for precise control of the degassing process

- Multiple power supply options to fit your facility's voltage and frequency specifications

- Additional safety features, such as emergency stop buttons and protective covers, to ensure operator safety

With our customization options, you can be sure that our Rotary Degassing Unit will meet your specific requirements and improve the efficiency and quality of your aluminum smelting process.

Contact Us for Your Customized Solution

Interested in our Rotary Degassing Unit and how it can be customized to fit your specific needs? Contact us today to discuss your requirements and receive a personalized quote.

Packing and Shipping:

Packaging and Shipping of Rotary Degassing Unit

The Rotary Degassing Unit is carefully packaged to ensure safe and secure delivery to our customers.

The unit is first placed in a sturdy wooden crate, which is then sealed and reinforced with wooden planks on all sides. This provides extra protection during shipping and handling.

Inside the crate, the unit is wrapped in multiple layers of protective material, such as foam padding and bubble wrap, to prevent any damage during transit.

The crate is then labeled with the necessary shipping and handling information, including the product name, weight, dimensions, and destination address.

For international shipments, the necessary customs forms and documents are also included with the package.

Once the package is prepared and sealed, it is loaded onto a secure and reliable shipping carrier for transport to the designated destination.

Our team takes great care in ensuring that the Rotary Degassing Unit is packaged and shipped with the utmost attention to detail and quality to guarantee its safe arrival to our customers.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!